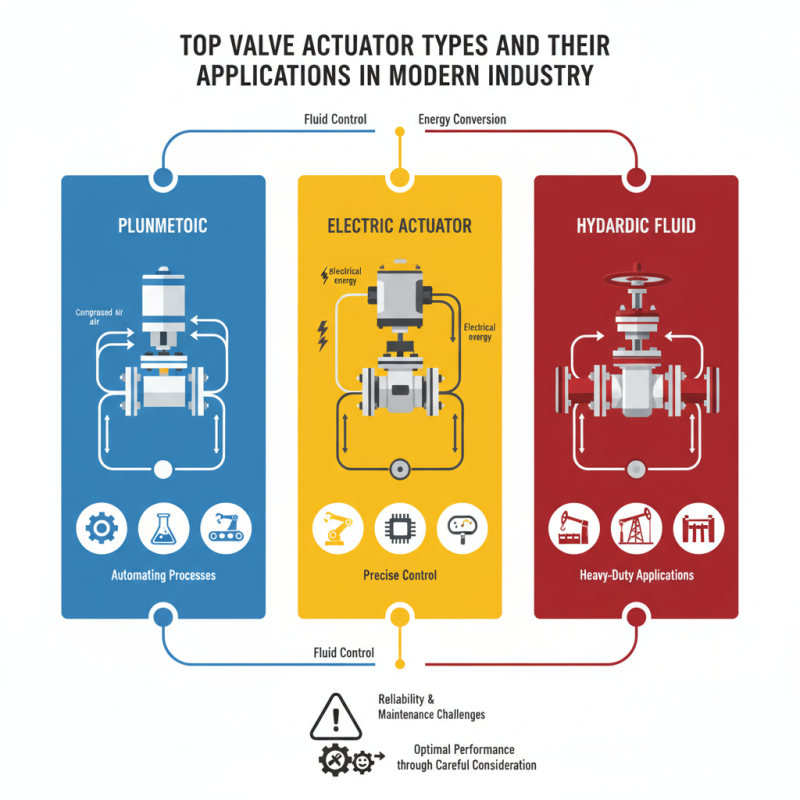

Top Valve Actuator Types and Their Applications in Modern Industry?

In modern industry, valve actuators play a crucial role in controlling fluid flow. These devices convert energy into mechanical motion, ensuring efficient operation in various applications. From automating processes to enhancing safety, valve actuators are integral to many systems.

Different types of valve actuators exist, each serving unique functions. Pneumatic actuators rely on compressed air for movement. Electric actuators use electrical energy, providing precise control. Hydraulic actuators offer high force and are ideal for heavy-duty applications. Understanding these types aids in selecting the right actuator.

Despite their importance, there are challenges in actuator implementation. Reliability can be an issue, with potential mechanical failures. Proper maintenance is necessary to avoid downtime. Also, choosing the wrong type can lead to inefficiencies. Therefore, careful consideration is required for optimal performance in any industrial setting.

Overview of Valve Actuators and Their Importance in Industry

Valve actuators play a critical role in modern industries. They control the flow of fluids in pipes and systems. This precision is essential for efficient operations. According to a recent industry report, valve actuators account for about 20% of automation costs in process industries. Optimizing actuator performance can reduce these costs significantly.

In manufacturing settings, electric and pneumatic actuators are the most common types. Electric actuators provide precise control. However, they can be costly to maintain. Pneumatic actuators, on the other hand, are simpler and usually more reliable. Many facilities are now transitioning towards smart actuators. These devices allow for real-time monitoring and analytics. However, integrating these technologies requires significant investment.

Despite these advancements, challenges remain. Issues like wear and tear can cause performance drops over time. Many companies are unaware of how often they should replace actuators. This can lead to efficiency losses. Training staff on these technologies is also an ongoing need. Proper knowledge can help in proactive maintenance.

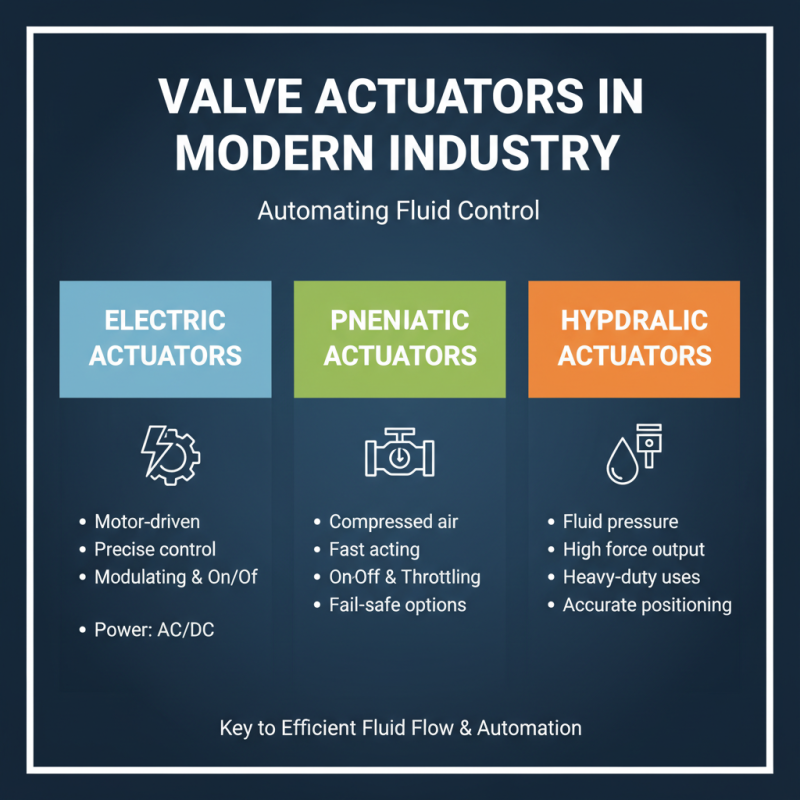

Types of Valve Actuators: Electric, Pneumatic, and Hydraulic Explained

In modern industry, valve actuators play a crucial role. They automate the operation of valves, ensuring efficient control of fluid flow. Three main types of actuators are commonly used: electric, pneumatic, and hydraulic.

Electric actuators are popular due to their precision and ease of integration with control systems. They convert electrical energy into mechanical motion. This allows for accurate positioning of valves, making them ideal for applications that require tight control. However, electric actuators often depend on a stable power source. This reliance can be a drawback in remote locations where electricity is unstable or unavailable.

Pneumatic actuators utilize compressed air for operation. They offer rapid movement and high force output, making them suitable for heavy-duty applications. However, their performance can be affected by the supply of compressed air. A drop in air pressure may lead to erratic valve performance. Meanwhile, hydraulic actuators use liquids to generate movement. They can handle larger loads but require careful maintenance to prevent leaks. Each actuator type has distinct advantages and challenges, making the choice highly application-dependent.

Key Applications of Valve Actuators in Various Industrial Sectors

In modern industry, valve actuators play a crucial role. They automate the opening and closing of valves, ensuring smooth operations. In the oil and gas sector, these actuators help control the flow of liquids and gases. They maintain safety and efficiency. But, not all systems work perfectly. A small malfunction can lead to significant delays.

In the chemical industry, the need for precision is paramount. Actuators control the intricate processes of mixing and separating substances. They ensure the correct chemical reactions occur. However, wear and tear can take a toll on these devices. Regular maintenance is essential, yet often overlooked.

Water treatment facilities also rely on actuators. They regulate water flow and chemical dosages effectively. This automation aids in meeting environmental standards. Still, there can be issues with calibration. A slight error might disrupt the entire operation. Every industry has unique needs. Understanding these differences helps in choosing the right actuator.

Top Valve Actuator Types and Their Applications in Modern Industry

| Actuator Type | Mechanism | Key Industries | Applications |

|---|---|---|---|

| Electric Actuators | Electric motor-driven | Water Treatment, HVAC | Flow control, valve positioning |

| Pneumatic Actuators | Compressed air-driven | Oil & Gas, Chemical | Rapid valve movement, safety systems |

| Hydraulic Actuators | Hydraulic fluid-driven | Power Generation, Mining | Heavy machinery operation, throttle control |

| Manual Actuators | Hand-operated | Food & Beverage, Pharmaceutical | Local flow control, maintenance tasks |

| Smart Actuators | Integrated sensor technology | Manufacturing, Automation | Automated control systems, data collection |

Selection Criteria for Choosing the Right Valve Actuator

When selecting a valve actuator, consider the application requirements. Think about the type of valve you are using. Different valves require specific actuation types. For example, ball valves often need fast-acting actuators. In contrast, gate valves may require slow, precise movements. An actuator's speed and torque ratings play crucial roles in performance.

Another essential factor is the environment where the actuator will operate. High temperatures or corrosive atmospheres can affect performance. Use actuators made from durable materials. Also, think about the power source. Electric, pneumatic, and hydraulic actuators each have unique advantages. Electric actuators are typically easier to maintain but may struggle in hazardous areas.

Efficiency is key, but it’s also about reliability. Will the actuator perform under stress? Examine its response time and durability. Think about a backup plan if an actuator fails. It's crucial to evaluate these aspects, despite their complexity. An actuator may seem ideal at first glance but may not suit specific demands later on. Take the time to conduct thorough research and testing. This ensures that you choose the most suitable actuator for your system's unique needs.

Future Trends in Valve Actuator Technology and Applications

The future of valve actuator technology is promising. Innovations are focused on smart automation. Sensors and IoT integration are becoming common. These advancements enhance monitoring and control, improving efficiency.

Tips: Consider predictive maintenance. It can reduce downtime and increase reliability. Smart actuators can alert teams before failures occur.

Sustainability is also a priority. Electric and pneumatic actuators are evolving to reduce energy consumption. Manufacturers are exploring new materials that are environmentally friendly. However, these developments come with challenges in production costs and durability.

Smart actuators do have limitations. They rely on stable internet connections. Connectivity issues could disrupt operations. Engineers must continuously assess interoperability across systems to ensure smooth operations.

Top Valve Actuator Types and Their Applications in Modern Industry

This chart illustrates the distribution of applications for different types of valve actuators in modern industries. Electric actuators lead in usage, followed by pneumatic, hydraulic, and mechanical actuators, highlighting the evolving landscape of valve actuator technology.

Related Posts

-

2026 Top Valve Actuator Types You Should Know?

-

2025 Top 10 Valve Actuators Revolutionizing Industrial Automation with 25 Percent Efficiency Increase

-

Exploring the Future of Valve Automation and Control in Sustainable Energy Solutions

-

How to Choose the Right Asco Solenoid Valve for Your Application

-

Top 10 Benefits of Using Globe Valves in Industrial Applications

-

Top Electric Valves Types You Should Know About?