Top Electric Valves Types You Should Know About?

Electric valves play a crucial role in various industries, including oil and gas, water management, and manufacturing. According to a recent report by Research and Markets, the electric valve market is projected to grow by 6% annually, driven by automation needs. These devices are key for controlling fluid flow, ensuring efficiency and safety in operations.

Understanding the different types of electric valves is essential for selecting the right one. Proportional valves, solenoid valves, and rotary valves serve unique functions, impacting system performance. The choice often depends on specific applications, and there are cases where improper selection can lead to inefficiencies. Data shows that up to 20% of installed valves perform suboptimally, highlighting the importance of accurate specifications.

Moreover, the integration of electric valves in smart systems enhances monitoring and management. However, not all electric valves are designed equally. Some may experience issues such as wear and tear, raising questions about their long-term reliability. It’s crucial for industries to assess their needs carefully to avoid costly mistakes.

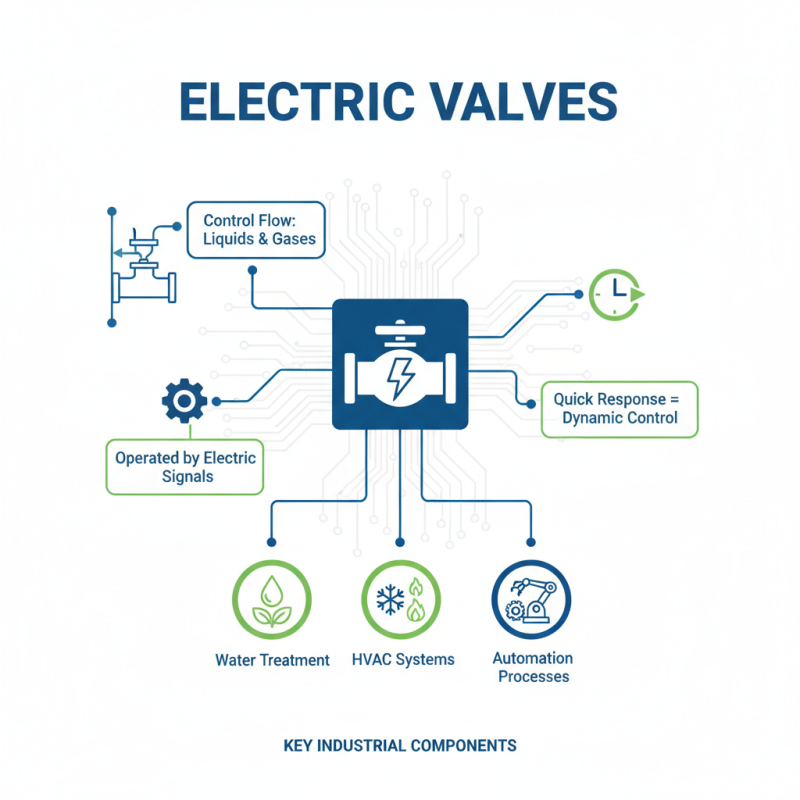

Overview of Electric Valves and Their Applications

Electric valves are crucial components in various industries. They control the flow of liquids and gases. These valves operate through electric signals, allowing for precise control. You can find them in water treatment plants, HVAC systems, and automation processes. Their ability to respond quickly makes them ideal for dynamic environments.

Among the different types of electric valves, proportional valves are significant. They adjust the flow gradually based on the input signal. This can help control pressure more accurately. On-off valves are common as well. They provide simple and direct control for fluid movement. However, choosing the right type can be challenging. Each has its own unique benefits and drawbacks.

Some electric valves require regular maintenance to function properly. Neglecting this can lead to operational failures. It’s essential to pay attention to their performance. Also, understanding the application is vital. Sometimes, the best choice requires thorough research. The learning curve can be steep, but it is worth the effort for optimal performance.

Types of Electric Valves: A Comprehensive Breakdown

Electric valves are crucial components in various industries. They control fluid flow and enhance system efficiency. Understanding different types of electric valves is essential for optimal performance.

One common type is the solenoid valve. This valve uses electromagnetic coils to switch flow on and off. They are compact and operate quickly, making them ideal for automated systems. According to recent studies, solenoid valves are prevalent in the chemical and irrigation sectors, accounting for about 35% of the market share.

Another type is the electric actuator valve. These valves allow for precise control of flow rates. They are commonly used in HVAC systems and water treatment facilities. Data indicates that electric actuators can improve energy efficiency by up to 40% when integrated with smart technologies. However, installation can be complex, requiring skilled technicians. Understanding each type's unique strengths and weaknesses is vital for effective application.

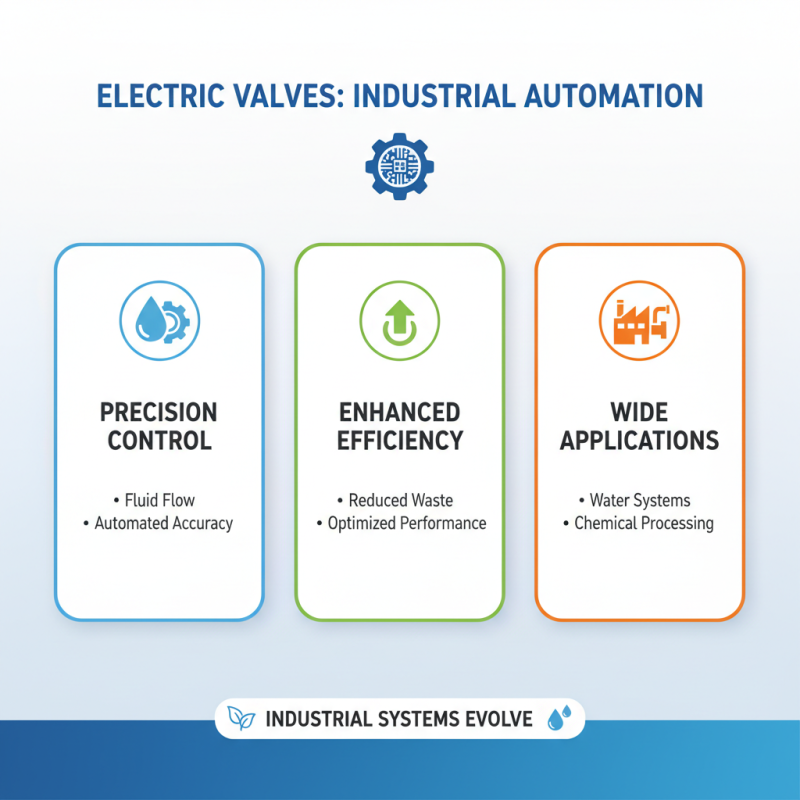

Advantages of Using Electric Valves in Industrial Systems

Electric valves are increasingly popular in industrial systems. Their automation offers precise control over fluid flow. This precision can enhance efficiency and reduce waste. Many industries benefit from using electric valves. They handle a variety of applications, from water systems to chemical processing.

One key advantage of electric valves is their ability to operate remotely. Operators can control them from a distance, improving safety and efficiency. This can be crucial in hazardous environments. Moreover, electric valves usually require less maintenance than manual options. However, they may need occasional troubleshooting.

Another benefit is their energy savings. Electric valves consume less energy when optimally used. This can lead to significant cost reductions over time. Yet, this technology is not perfect. Reliability issues can arise if not correctly installed. Operators should be aware of these challenges. Overall, electric valves can transform industrial operations when used thoughtfully.

Key Features to Consider When Choosing Electric Valves

Choosing the right electric valve can significantly impact your project’s efficiency. Several key features are essential to consider. Understanding these elements can help you make an informed decision.

Flow rate is a crucial factor. Electric valves come in various sizes. Selecting the right size ensures optimal flow control. According to industry data, improper sizing can lead to up to a 30% efficiency loss. Pressure rating is also vital. Ensure the valve can withstand the system pressure. If pressure limits are exceeded, valve failure may occur.

Material selection matters. Corrosion resistance is key for long-term performance. Common materials include stainless steel and plastic. Each has its advantages depending on the application. Pay attention to the environment in which the valvewill operate. A valve suited for hot liquids may not perform well in cold conditions.

Tips: Always analyze your system’s specifications. Avoid common pitfalls like mismatched pressure ratings. Consider future maintenance needs. If access is limited, select maintenance-friendly designs.

In summary, careful consideration of these factors is paramount. By focusing on critical features, you can enhance operational reliability. Electric valves represent a significant investment. Make sure your investment yields the desired results.

Top Electric Valves Types You Should Know About

This chart displays the most common types of electric valves and their respective usage percentages in various industries. Understanding these types can help you make informed decisions when selecting electric valves for your projects.

Maintenance Tips for Optimal Electric Valve Performance

Electric valves are crucial for various industrial applications. However, their performance can degrade over time. Regular maintenance is essential to keep them functioning optimally. Industry reports indicate that 30% of electric valve failures stem from inadequate upkeep.

Routine inspections are vital. Visual checks can reveal leaks or corrosion. Operators should pay attention to signs of wear and tear. It’s recommended to clean the actuator and check the electrical connections. Some maintenance tasks are neglected, leading to further issues down the line.

Calibration is another key aspect. Properly set calibration ensures efficient operation. Research shows that improperly calibrated valves can reduce flow efficiency by up to 15%. This could result in increased energy costs. Regular training for personnel on maintenance practices can prevent mistakes. Awareness is key. Companies must prioritize ongoing education to improve valve reliability.

Top Electric Valves Types You Should Know About

| Valve Type | Description | Applications | Maintenance Tips |

|---|---|---|---|

| Solenoid Valve | A valve that uses an electromechanical solenoid to control the flow of fluid. | Hydraulic, pneumatic systems, and irrigation. | Regularly check for leaks and ensure proper voltage is supplied. |

| Motorized Ball Valve | A valve that provides on/off control of fluid flow with a motor actuator. | Water supply systems, gas pipelines, and HVAC applications. | Lubricate the stem regularly, and inspect electrical connections. |

| Electric Gate Valve | A valve that controls flow in a pipeline, using an electric motor for actuation. | Water treatment plants, chemical processing, and fire protection systems. | Ensure proper sealing and inspect for corrosion in the body. |

| Electric Butterfly Valve | A valve that uses a rotating disc to regulate flow; operated by an electric actuator. | HVAC systems, water distribution, and waste treatment. | Check the actuator for proper function, and clean the disc regularly. |

Related Posts

-

What is a Gas Shut Off Valve and Why You Need One for Your Safety

-

Exploring the Benefits of Installing a Water Pressure Relief Valve in Your Home Plumbing System

-

10 Essential Flow Control Tips to Optimize Your Workflow and Productivity

-

What is a gas shut off valve and how does it work?

-

Top 10 Benefits of Using Automatic Valves in Industrial Applications

-

Top 10 Benefits of Using Globe Valves in Industrial Applications