Top 10 Valve and Automation Solutions to Boost Your Operations?

In the ever-evolving realm of valve and automation, companies seek innovative solutions to improve efficiency. Industry expert Dr. Sarah Johnson, a leading figure in process automation, states, “The right valve and automation technologies can unlock significant operational potential.” This sentiment resonates with many organizations looking to enhance their industrial processes.

Valves and automation hold critical importance in modern operations. They influence everything from safety to productivity. However, many businesses still overlook key advancements. Investing in the latest technologies can seem daunting. But, the rewards often outweigh the risks. By embracing automation, companies can streamline their workflows and reduce manual errors.

Not every method will fit every organization. Each facility faces unique challenges. Some may struggle with legacy systems, while others might resist change. Understanding these nuances is crucial. As the industry progresses, reflecting on technological adoption will be essential to remain competitive. Prioritizing the right solutions in valve and automation will ultimately shape the future of operations.

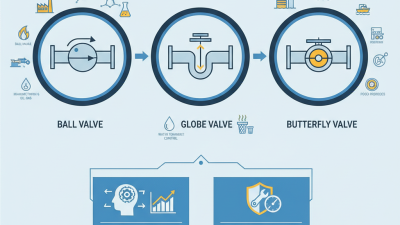

Key Trends in Valve and Automation Technologies for Enhanced Efficiency

In today’s fast-paced industrial landscape, optimizing operations is crucial. Valve and automation technologies are integral to increasing efficiency. Key trends are shaping the future of this field. One significant trend is the rise of smart automation. Sensors and IoT devices improve monitoring and control. This allows for real-time data analysis, which enhances decision-making.

Here are some tips. Assess your current systems. Identify pain points and areas for improvement. Consider integrating predictive maintenance technology. It minimizes downtime and can save money. Investing in training for staff is equally important. Skilled employees can leverage new technologies effectively.

Another trend is the move toward sustainable practices. Eco-friendly designs reduce energy consumption. Companies focus on solutions that support environmental goals. Regular audits can track your progress in this area. However, implementing change can be challenging. Resistance to new methods may arise. Open communication is vital for easing transitions.

Impact of IoT and Smart Valves on Streamlining Operations

The adoption of IoT and smart valves is transforming operational efficiency across various industries. Recent studies indicate that connected devices can reduce maintenance costs by up to 30%. This is achieved through real-time monitoring and predictive analytics. Smart valves can communicate data on fluid flow and pressure continuously. The insights gained help to prevent leaks and failures.

In a world increasingly reliant on data, the significance of automation cannot be overstated. According to industry reports, implementing smart valve technology can enhance efficiency by as much as 25%. These valves can adjust automatically based on system demands. However, not all systems are equipped to handle such advancements seamlessly. Integration challenges often arise, leading to missed opportunities.

Moreover, some companies still rely on traditional valves. This often results in increased downtime and inefficiency. A significant percentage of organizations are hesitant to invest in new technology. Consequently, this holds back potential gains in productivity. As industries evolve, the real challenge lies in balancing the performance of current systems with innovative solutions.

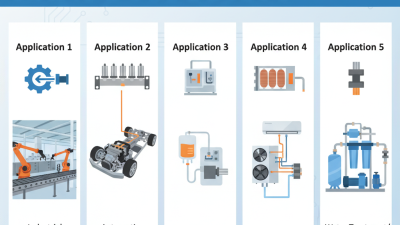

Case Studies: Successful Implementations of Automation Solutions

Automation has transformed many industries, leading to improved efficiency and reduced operational costs. One notable case involved a manufacturing plant that implemented valve automation solutions. By integrating smart sensors, they achieved real-time monitoring. This allowed for quick adjustments, reducing downtime significantly. However, initial setup was challenging. Staff training proved to be a hurdle, as some employees resisted changes.

In another example, a water treatment facility revamped its control systems. They utilized automated valves to manage flow rates better. This reduced water wastage, improving overall sustainability. Nonetheless, the integration faced setbacks due to outdated infrastructure. The team had to spend extra time troubleshooting compatibility issues. Lessons learned include the importance of planning and adaptability when adopting new technologies. These experiences highlight that while automation offers tremendous benefits, careful consideration of implementation is essential.

Cost-Benefit Analysis of Upgrading Valve Systems for Performance Gains

Upgrading valve systems can significantly enhance operational performance. A cost-benefit analysis reveals that investing in better automation solutions often leads to substantial long-term savings. Improved efficiency reduces energy consumption and maintenance costs. This creates a compelling financial incentive for businesses.

Tips: Consider pilot projects before a full upgrade. Testing a new system on a smaller scale can unveil unforeseen issues. It's essential to involve key stakeholders in the discussion. Their insights can steer the decision in a positive direction.

In some cases, organizations hesitate to upgrade. They worry about the upfront investment. However, delaying improvements may lead to higher costs over time. Old systems often fail, leading to downtime and lost revenue. Regular evaluations can help you stay ahead and avoid these pitfalls. It's important to weigh the immediate costs against potential returns.

Future Outlook: Innovations in Valve Design and Automation Integrations

The future of valve design and automation integrations is promising. Recent industry reports indicate that the global valve market is expected to reach $100 billion by 2025. Innovations in smart technology and IoT are reshaping this landscape. Enhanced connectivity allows for real-time monitoring, leading to more efficient operations.

Automation improves accuracy and reduces manual errors. Machines equipped with AI can predict potential failures before they happen. This proactive approach minimizes downtime and maintenance costs. However, integrating these advanced systems can be challenging. Many facilities still struggle with outdated infrastructure, causing delays in adoption.

Another key aspect is sustainability. Companies are increasingly focused on environmentally friendly solutions. Reports show a 20% increase in demand for eco-friendly valves between 2020 and 2023. Yet, there is still a gap in awareness. Not all organizations recognize the long-term benefits of sustainable practices. Emphasizing education and training can bridge this divide, helping industries work towards a more efficient future.

Related Posts

-

2026 How to Choose the Right Safety Relief Valve for Your System?

-

Top Electric Valves Types and Their Applications in Modern Industry?

-

How to Choose the Right Automatic Valve for Your Industrial Needs

-

Exploring the Future of Valve Automation and Control in Sustainable Energy Solutions

-

Top 5 Asco Solenoid Applications and Benefits You Need to Know

-

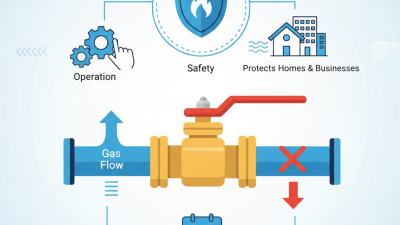

What is a gas shut off valve and how does it work?