2026 Top Valve Actuator Types You Should Know?

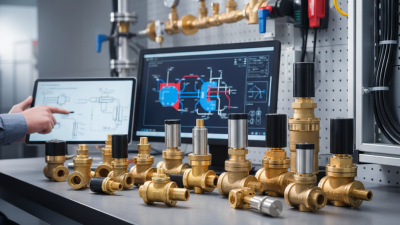

In the realm of industrial automation, understanding valve actuators is crucial. These devices play an essential role in controlling flow within various systems. Choosing the right valve actuator can significantly impact efficiency and safety.

In 2026, several types of valve actuators are gaining attention. Electric, pneumatic, and hydraulic actuators each have unique strengths. For instance, electric actuators are often praised for their precision and ease of installation. However, they may not always handle high-pressure situations effectively.

Pneumatic actuators, on the other hand, excel in speed and reliability. Yet, they can be limited by air supply constraints. The hydraulic variants offer immense force but require careful maintenance. Understanding these nuances helps in selecting the most suitable actuator for specific applications. As technologies evolve, the landscape of valve actuators continues to change, prompting reflection on their optimal use in our systems.

Overview of Valve Actuators: Importance and Applications

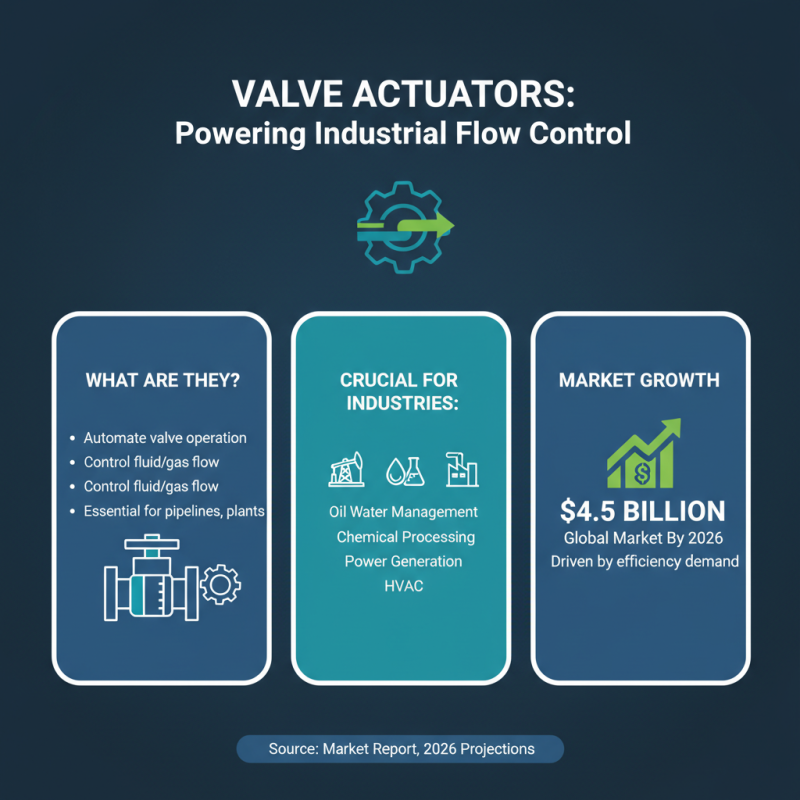

Valve actuators play a crucial role in various industries, from oil and gas to water management. They are essential for controlling the flow of fluids and gases through valves. According to a market report, the global valve actuator market is expected to reach $4.5 billion by 2026. This growth highlights the increasing importance of efficient control mechanisms in industrial processes.

Understanding the types of valve actuators available is critical. Electric, pneumatic, and hydraulic actuators each serve unique applications. Electric actuators are favored for precise control. Pneumatic actuators excel in high-speed operations. Hydraulic actuators are powerful but often more expensive. Industry data shows that 45% of manufacturing facilities prefer electric types for energy efficiency.

Tips: Regular maintenance of actuators is vital. Check for wear and tear. Ensure that the actuator settings match the application requirements. A misaligned actuator can lead to costly downtime. Be aware that not all actuators are suitable for every environment. Consider factors such as temperature and pressure. This awareness can improve operational longevity.

Ultimately, selecting the right valve actuator is not straightforward. Factors like process requirements and safety standards must be considered. A mismatch can hinder performance. Continuous evaluation of actuator performance is crucial. Use data analytics to monitor efficiency and reliability. This attention can lead to enhanced productivity and reduced costs over time.

Types of Valve Actuators: Exploring Mechanical, Hydraulic, and Electric Models

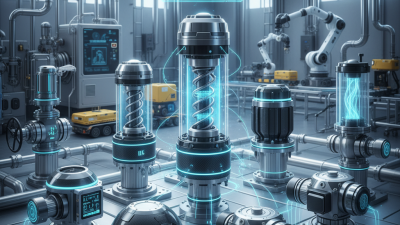

Valve actuators play a critical role in various industrial processes. They are essential for controlling valve movement and ensuring efficient operation within systems. There are three main types: mechanical, hydraulic, and electric actuators. Each type has unique features and applications, making them suitable for distinct environments.

Mechanical actuators are often found in simpler systems. They rely on manual power or basic mechanical forces. Their simplicity makes them less costly and easy to maintain. However, they might not provide precise control for complex operations. According to recent industry reports, mechanical actuators account for about 30% of the global market share in valve actuation.

Hydraulic actuators utilize fluid power for operation. They are powerful and capable of handling larger valves. These actuators provide significant torque, making them ideal for heavy-duty applications. Despite their efficiency, hydraulic systems can be complex and may leak over time. Reports suggest that hydraulic actuators represent roughly 50% of the industry market, highlighting their prevalence in demanding environments.

Electric actuators are gaining momentum due to their precision and energy efficiency. They offer advanced control options and can be integrated with modern automation solutions. However, the initial investment can be higher compared to mechanical and hydraulic types. Still, industry forecasts indicate a 15% annual growth in electric actuators, showcasing their increasing reliance in various sectors. Understanding these types is crucial for selecting the right actuator for specific operational needs.

2026 Top Valve Actuator Types

This chart displays the distribution of different types of valve actuators in 2026. The focus is on Mechanical, Hydraulic, and Electric models, which are essential for valve control in various industries.

Advantages and Disadvantages of Each Valve Actuator Type

When exploring valve actuator types, it’s vital to weigh their advantages and disadvantages.

Electric actuators are among the most common choices.

They are efficient and easy to control. Yet, they come with a reliance on a power supply,

which can be a significant drawback. In environments where power outages are common,

this dependence can be a serious flaw. According to industry reports, nearly

30% of companies cite power reliability as an ongoing concern.

Pneumatic actuators, on the other hand, offer rapid movement and high force output.

Many industries prefer them for their speed. However, they require a compressed air source,

which can introduce complications. Leakage in air lines often leads to inefficiencies.

Furthermore, regular maintenance is required to prevent breakdowns.

This adds to operational costs, which is something businesses overlook too often.

Hydraulic actuators provide remarkable strength and precision. They excel in heavy-duty applications.

The downside? They can be noisy and produce vibrations. Furthermore,

hydraulic fluid leaks can create environmental risks. The balance of power and potential issues is crucial.

Many firms need to consider these factors closely.

Key Factors to Consider When Selecting a Valve Actuator

When selecting a valve actuator, various factors come into play. The actuator type must match the valve’s function. Electric actuators are popular in many industries due to their precision and ease of control. According to a recent report, electric actuators account for 35% of the market share. This highlights their significance in operational efficiency.

Another crucial factor is the application environment. Actuators in hazardous settings require specific housing to protect against environmental factors. There are significant differences in performance ratings depending on temperature and pressure conditions. A study found that 25% of actuators failed due to inappropriate environmental considerations. It's vital to evaluate these conditions carefully before making a decision.

Moreover, maintenance and costs cannot be overlooked. Regular maintenance impacts longevity. It’s estimated that poorly maintained actuators can incur up to 30% higher operational costs. Companies often underestimate this, leading to unexpected expenses. Evaluating machine wear and the maintenance schedule will improve overall performance. Often, a little foresight can prevent costly failures down the road.

2026 Top Valve Actuator Types You Should Know

| Actuator Type | Application | Advantages | Disadvantages | Key Considerations |

|---|---|---|---|---|

| Electric Actuator | Water Treatment, HVAC | High precision, easy integration | Sensitive to power supply issues | Voltage requirements, control system compatibility |

| Pneumatic Actuator | Oil & Gas, Chemical Processing | Fast operation, high force | Requires compressed air supply | Air quality, pressure range |

| Hydraulic Actuator | Heavy Industry, Marine | Powerful and durable | Complex system, costly | Fluid compatibility, leakage prevention |

| Spring Return Actuator | Safety Valves, Emergency Shut-offs | Reliable fail-safe operation | Slower response time | Spring force, return time |

| Smart Actuator | Industrial Automation, IoT | Enhanced monitoring, remote access | Higher initial cost | Network security, software compatibility |

Future Trends in Valve Actuator Technology and Innovation

The future of valve actuator technology is poised for significant advancements. A recent report estimates that the valve actuator market will reach $5.9 billion by 2027, driven by increasing industrial automation. Such growth indicates a shift towards more intelligent systems. Smart actuators are now integrating with IoT technology, enabling real-time monitoring. This connectivity is crucial for predictive maintenance. By 2025, approximately 50% of valve actuators will be smart and connected to data platforms.

Innovations in materials also play a key role. New composite materials can enhance durability and performance. As industries focus on sustainability, these materials reduce environmental impact. However, this comes with challenges. Developing reliable, lightweight materials requires time and investment. There's a balance between cost and quality that companies must navigate. Additionally, cybersecurity concerns grow as devices become more interconnected. Protecting data from breaches is essential for widespread adoption.

Emerging trends indicate the integration of Artificial Intelligence. Algorithms can optimize performance and efficiency. However, relying too much on automation can lead to overconfidence. Human operators should remain involved in the process. Striking the right balance between tech and human oversight is crucial for success in the evolving landscape of valve actuator technology.

Related Posts

-

2025 Top 10 Valve Actuators Revolutionizing Industrial Automation with 25 Percent Efficiency Increase

-

Exploring the Future of Valve Automation and Control in Sustainable Energy Solutions

-

Top 10 Benefits of Using Automatic Valves in Modern Plumbing Systems

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

How to Locate and Use a Natural Gas Shut Off Valve Safely

-

How to Choose the Right Asco Solenoid Valve for Your Application