Top 10 Flow Control Techniques for Efficient Process Management?

Effective process management is crucial in today's fast-paced industries. "Flow control" plays a significant role in enhancing operational efficiency. According to Dr. Emily Rivera, a leading expert in process optimization, "The right flow control techniques can transform how businesses operate." Her insights emphasize the value of strategic flow management in improving productivity.

In many organizations, flow control techniques remain underutilized. Misalignment of processes often leads to bottlenecks. For instance, a production line lacking proper flow control can experience delays and increased costs. This inefficiency highlights the need for businesses to adopt innovative flow control methods. However, not all techniques fit every business model. Companies must evaluate their specific needs to implement effective solutions.

Challenges persist in achieving optimal flow control. Organizations may struggle to recognize the right tools and strategies for their unique circumstances. The key is to focus on continuous improvement. Implementing the best flow control techniques requires regular evaluation and adaptation. The journey toward efficient process management is ongoing, and there is always room for reflection.

Top 10 Flow Control Techniques for Efficient Process Management

Efficient process management greatly relies on effective flow control techniques. These methods help streamline activities, minimize waste, and improve productivity. Understanding what works best for your operations is crucial. It's common to overlook the power of simple techniques.

One powerful flow control technique is visualization. Mapping out processes can reveal bottlenecks. Visual tools help teams see where delays occur. Regularly updating these maps is essential. Changes in workflows can create new challenges. Don’t forget to keep them current.

Another useful tip is to incorporate feedback loops. Collect input from team members regularly. They often notice issues that managers overlook. However, not all feedback is actionable. Analyze it wisely. Focus on what can truly improve the process. Make adjustments based on prioritized feedback.

Lastly, consider the use of automation selectively. Automating tasks can save time, but not every process benefits from it. Evaluate the effectiveness of automation frequently. Some workflows may experience disruptions from too much automation. Keep a close eye on performance metrics to ensure efficiency.

Understanding Flow Control: Definitions and Key Concepts in Process Management

Flow control in process management is crucial for maintaining efficiency. It refers to the various methods used to regulate and optimize workflows. Understanding these techniques can help organizations streamline operations and reduce bottlenecks. Key concepts include feedback loops and real-time monitoring. These strategies allow for quick adjustments when issues arise.

Effective flow control involves clear definitions of roles and responsibilities. Everyone in the team should know their tasks. This clarity prevents confusion and enables smoother transitions between different stages of a process. Visual aids like flowcharts can enhance understanding and communication. However, implementing these tools is not always straightforward. It might require an adjustment period for the team to adapt.

Another challenge is ensuring that the flow control methods remain flexible. Rigid systems can stifle creativity and responsiveness. Organizations should encourage input from team members. Their insights can reveal inefficiencies that management may overlook. Finding a balance between structure and flexibility is critical for true process improvement. Sometimes, the best approach is to try different techniques and see what works best.

Top 10 Flow Control Techniques for Efficient Process Management

The Role of Lean Manufacturing in Streamlining Flow Control Techniques

Lean manufacturing plays a crucial role in streamlining flow control techniques. It focuses on eliminating waste while enhancing value. According to a 2022 report by the Lean Enterprise Institute, companies implementing lean practices saw a 25% increase in efficiency. This improvement directly impacts process management.

Flow control techniques, when aligned with lean principles, can reduce bottlenecks. For example, value stream mapping helps identify inefficiencies. It reveals steps that do not add value. In a study by MIT, 60% of manufacturers noted challenges in visualizing their process flows. Issues like unclear workflows often hamper performance. Companies need to reflect on these points for better outcomes.

Continuous improvement is essential in lean methodologies. Techniques such as Kanban and Just-In-Time inventory can enhance flow control. However, not all organizations realize their full potential. A 2023 report indicated that 40% of firms lack proper training in these techniques. This gap hinders effective implementation. Steps must be taken to address the knowledge blind spots within teams.

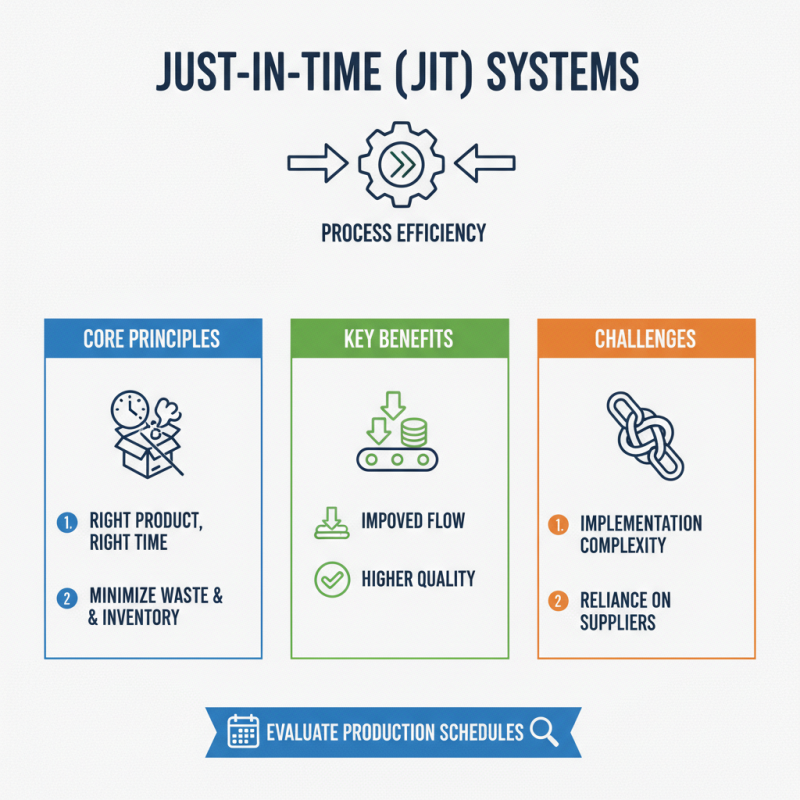

Analyzing the Impact of Just-in-Time (JIT) Systems on Process Efficiency

Just-in-Time (JIT) systems are crucial for enhancing process efficiency. These systems focus on producing the right amount of products at the right time. This minimizes waste and reduces inventory costs. JIT encourages companies to evaluate their production schedules rigorously. However, its implementation is not without challenges.

A key aspect of JIT is the demand-driven approach. Companies must accurately forecast customer demand. Misjudgments in demand can lead to shortages or excess inventory. Striking a balance can be difficult. Efficient communication with suppliers is essential. Delays can cripple an organization relying on JIT.

Moreover, employee training is vital in JIT systems. Workers need to adapt quickly to changes. A lack of proper training can slow down processes. Inflexibility can hinder the overall goal of efficiency. Continuous improvement should be a company mantra. Regular assessments can help identify weaknesses in the JIT system. Adaptation is a necessary step in the ever-changing market landscape.

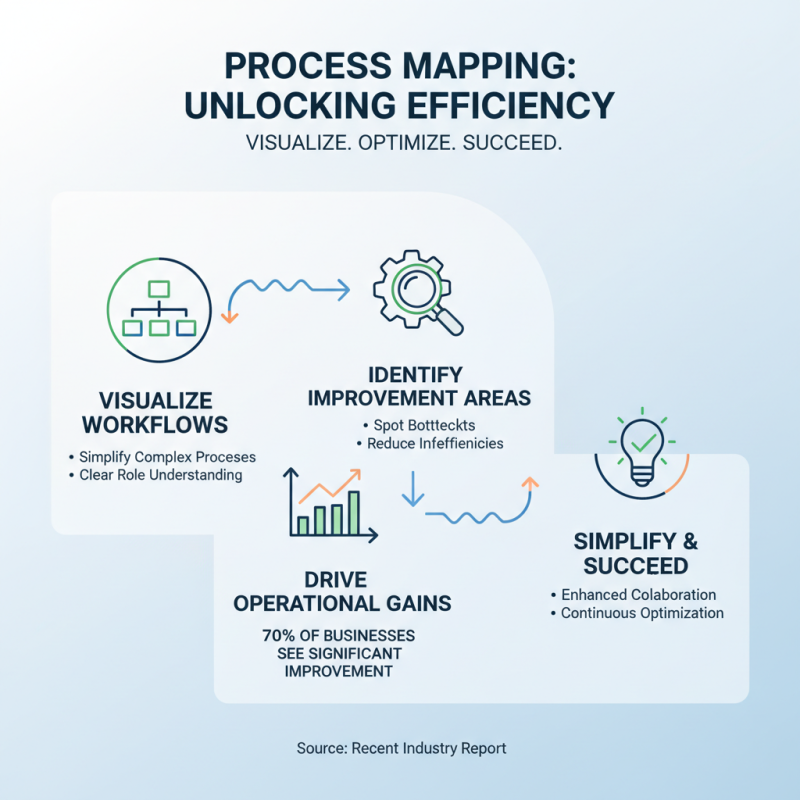

Utilizing Process Mapping for Enhanced Visualization and Flow Optimization

Process mapping is a powerful tool for visualizing workflows. It helps organizations identify bottlenecks and inefficiencies. According to a recent industry report, 70% of businesses that use process mapping see significant improvements in their operations. This technique simplifies complex processes. By creating a visual representation, everyone can understand their roles clearly. Flowcharts and diagrams reveal areas needing attention.

One study found that 55% of employees struggle with unclear processes. This can lead to wasted time and frustration. By utilizing process mapping, companies can tackle these issues. Improved communication is a key benefit. When employees comprehend workflows, they can collaborate more effectively. Enhanced visualization makes it easier to spot problems early.

However, there are challenges. Not all teams embrace process mapping. Some workers may resist change, fearing added workload. Additionally, creating detailed maps can be time-consuming. It requires ongoing effort and reflection to keep diagrams relevant. Regular reviews help maintain accuracy and engagement.

Conclusion

Effective process management is crucial for organizational success, and implementing robust flow control techniques plays a key role in achieving this. Understanding flow control involves grasping the fundamental definitions and concepts that underpin effective management practices. Lean manufacturing is instrumental in streamlining flow control techniques, enabling organizations to minimize waste and improve efficiency.

Additionally, the adoption of Just-in-Time (JIT) systems significantly enhances process efficiency by ensuring that materials and components are available only as needed. Utilizing process mapping allows for better visualization and optimization of workflows, leading to smoother operations. Furthermore, the integration of continuous improvement methodologies is essential for evolving flow control strategies, ensuring that organizations can adapt and thrive in a competitive landscape. In summary, mastering these flow control techniques empowers organizations to enhance their overall process management significantly.

Related Posts

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

2026 Top Valve Actuator Types You Should Know?

-

Maximizing Efficiency with Asco Solenoids in Modern Automation Systems

-

What is a Safety Valve and How Does It Work?

-

How to Locate and Use a Natural Gas Shut Off Valve Safely

-

Why You Should Choose the Right Gas Valve for Your Home Safety