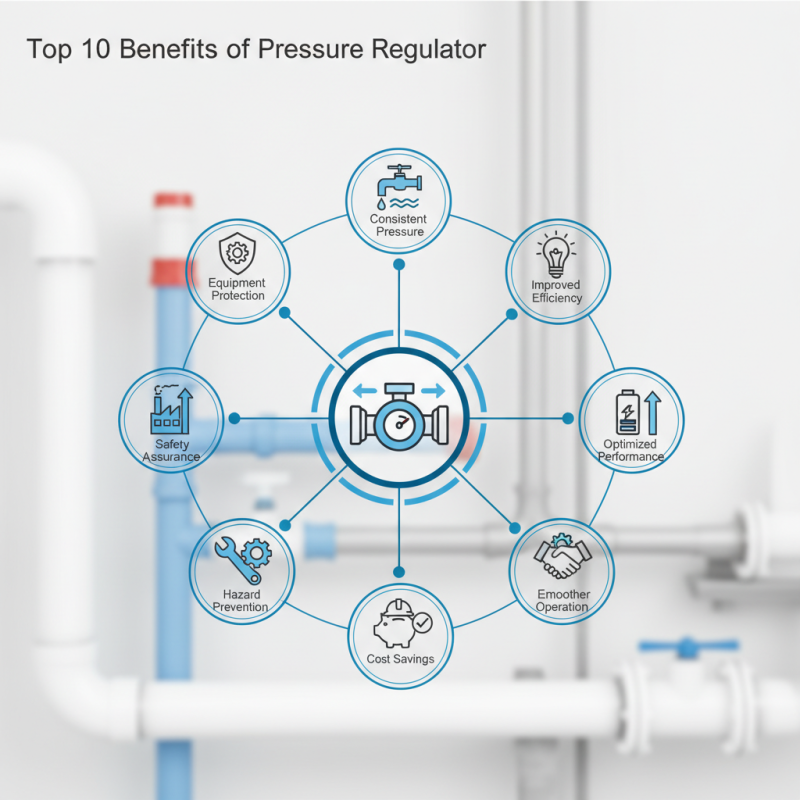

Top 10 Benefits of Using a Pressure Regulator Why You Need One?

A pressure regulator is an essential device in various applications. Whether in industrial settings, home use, or automotive systems, it controls the pressure of fluids or gases. By maintaining a consistent pressure, a pressure regulator safeguards equipment and ensures safety.

Many individuals overlook the importance of using a pressure regulator. The consequences can be significant. Fluctuating pressure can lead to equipment damage. It may also pose safety risks in specific environments. This can be especially true in high-pressure systems.

Moreover, using a pressure regulator can improve efficiency. It helps optimize performance and reduce energy waste. Users can experience better reliability in their systems. Awareness of these benefits is crucial. A pressure regulator is not just an accessory; it’s a vital component for smooth operation.

Understanding Pressure Regulators and Their Functionality

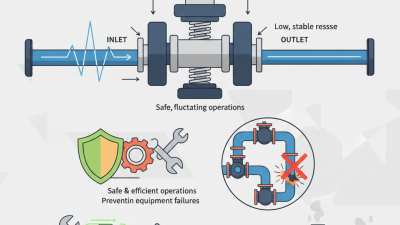

Pressure regulators play a crucial role in maintaining a stable flow of gas or liquid. They ensure the pressure remains consistent, preventing equipment damage or unsafe conditions. A well-functioning pressure regulator can enhance efficiency in various applications, from industrial machinery to home systems.

Understanding how pressure regulators work is essential. These devices reduce the high pressure from a source to a controlled lower pressure. They respond to fluctuations in pressure, adjusting automatically to maintain stability. This capability protects sensitive equipment and ensures optimal performance.

Tip: Regular inspection of pressure regulators can help identify potential issues early. Look for signs of wear or leaks.

In some cases, users may overlook the importance of these devices. They might think it's sufficient to manage pressure manually, but this can lead to dangerous situations. Properly using a pressure regulator can mitigate risks substantially.

Tip: Always refer to the manufacturer's guidelines for installation. Incorrect setup can compromise the regulator's effectiveness.

Taking time to understand your pressure regulator’s functionality can bring significant advantages. Keeping up with maintenance is often neglected but is vital to ensure longevity and safety.

Top 10 Benefits of Using a Pressure Regulator

| Benefit | Description |

|---|---|

| Pressure Control | Maintains a consistent pressure level to protect connected equipment. |

| Increased Safety | Reduces the risk of overpressure situations that can lead to accidents. |

| Energy Efficiency | Optimizes energy consumption by maintaining ideal operating pressures. |

| Equipment Longevity | Protects machinery and reduces wear and tear, extending equipment life. |

| Improved Performance | Ensures that systems operate under optimal conditions for better results. |

| Versatile Applications | Can be used in various industries from automotive to manufacturing. |

| Simple Maintenance | Low maintenance requirements and easy replacement procedures. |

| Cost-Effectiveness | Reduces potential costs related to equipment failure and downtime. |

| Enhanced Process Control | Allows for more precise control over industrial processes and operations. |

| Environmental Compliance | Helps meet regulations by reducing emissions and wastage. |

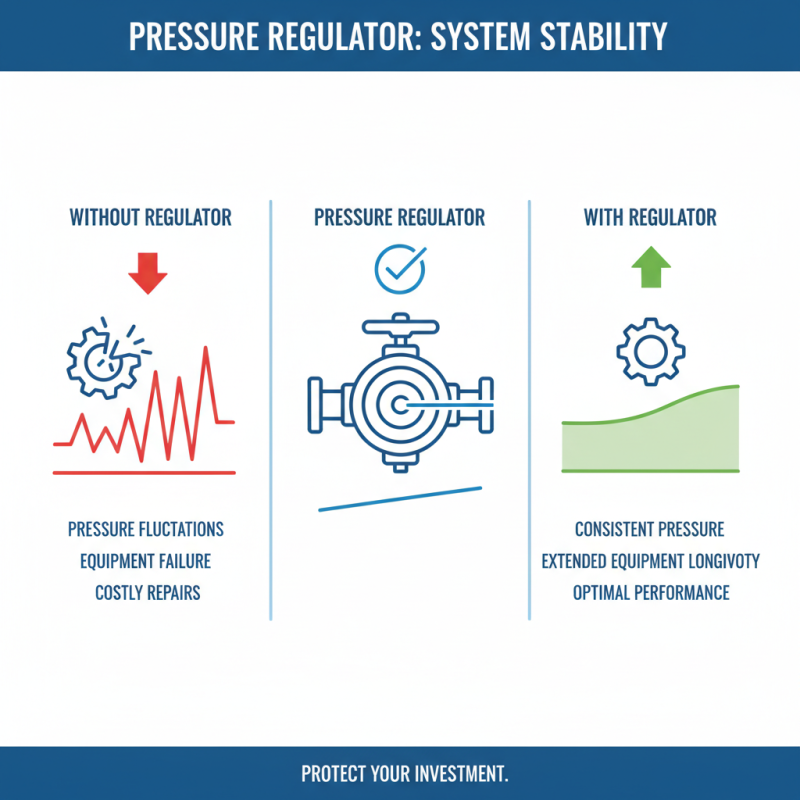

Key Advantages of Implementing a Pressure Regulator in Systems

A pressure regulator is an essential component in many systems. It ensures a consistent pressure, preventing sudden spikes or drops. This stability is crucial for equipment longevity and performance. When pressure levels fluctuate, equipment can fail. This inefficiency can lead to costly repairs and downtime.

Implementing a pressure regulator offers several key advantages. It enhances safety by reducing the risk of over-pressurization. In high-pressure environments, this is vital. A regulator helps maintain the correct pressure, minimizing hazards. Additionally, it improves energy efficiency, as systems operate optimally under controlled conditions. This not only saves energy but also reduces operational costs.

Another benefit is adaptability. Different applications require varying pressure levels. A good regulator can adjust to these needs. Sometimes, systems are set up poorly, which leads to inefficiencies. Regularly revisiting the configuration can prevent waste. While the advantages are clear, it's important to monitor and maintain these devices. Neglecting them can result in inconsistent pressure and performance issues.

Impact on Safety and Efficiency in Industrial Applications

In industrial settings, safety and efficiency are paramount. A pressure regulator significantly contributes to both. It helps maintain consistent pressure levels, reducing the risk of equipment failure. This consistency enhances operational reliability, which is crucial in high-stakes environments. Unregulated pressure can lead to bursts or leaks. These situations can be dangerous and costly.

Moreover, a pressure regulator improves energy efficiency. By controlling the pressure, it minimizes wasted energy in the system. This not only lowers operational costs but also lessens environmental impact. Regular maintenance of these devices is vital, however. Neglect can lead to malfunctions, causing safety hazards. Timely inspections can ensure that they perform optimally.

Failing to implement a pressure regulator could prove catastrophic. In some cases, industries have faced accidents due to pressure fluctuations. Ensuring the correct installation and setting is key. Operators must be knowledgeable about pressure settings. Continuous training is necessary, as complacency can be dangerous. The cost of overlooking these factors is high, both financially and in human safety.

Cost Savings and Maintenance Benefits of Using Pressure Regulators

Using a pressure regulator can significantly impact your costs and maintenance practices. One of the main benefits is the reduction in energy consumption. By precisely managing pressure levels, your equipment operates more efficiently. This can lead to lower utility bills over time. Energy wastage often happens with fluctuating pressures. A regulator can stabilize this, leading to substantial savings.

Maintenance costs can also be reduced. Equipment that operates at stable pressure is less likely to experience wear and tear. This often means fewer repairs. However, neglecting regular checks on the regulator can counteract these benefits. It's crucial to monitor its performance and ensure it functions properly. Recognizing minor issues early can save you from costly disruptions later. Regular maintenance is not merely an option; it’s a necessity.

Instability in pressure can also lead to material degradation. This is where pressure regulators prove invaluable. They create a consistent environment that prolongs the life of your equipment. An unstable system often results in leaks or ruptures, which are a hassle to fix. While the initial investment in a pressure regulator might seem high, the long-term savings in maintenance and energy costs often outweigh this concern. Consider these factors when evaluating your options for pressure management.

Top 10 Benefits of Using a Pressure Regulator

This chart illustrates the top benefits of using a pressure regulator, highlighting key factors such as cost savings, safety, and energy efficiency. Each benefit is rated on a scale from 1 to 10, showcasing their importance in industrial applications.

Applications Where Pressure Regulators are Essential for Performance

Pressure regulators play a key role in various industries. They ensure safe and stable operations in systems like gas lines or water supplies. In manufacturing, maintaining consistent pressure improves product quality. Without regulators, fluctuations can lead to defects. The precision they offer is vital in processes requiring exact measurements.

In medical applications, reliable pressure regulation is essential. Anesthesia machines need steady gas flow. Any variation can endanger patient safety. Similarly, in aquaculture, consistent water pressure is critical for fish health. Here, avoiding erratic pressure could prevent crops from failing.

In the food and beverage industry, pressure regulators help maintain product integrity. They ensure that carbonation levels remain stable in drinks. If pressure varies, it can alter taste and quality. However, not all applications use regulators properly. Choosing the right type requires careful consideration of specific needs and conditions. Users must avoid overlooking this crucial step.

Related Posts

-

What is a Pressure Regulator and How Does it Work?

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

Top 5 Relief Valve Options for Optimal Pressure Control in Industrial Applications

-

Why You Should Choose the Right Gas Valve for Your Home Safety

-

2026 How to Choose the Right Safety Relief Valve for Your System?

-

The Best 10 Pressure Control Valve Models for Optimal Performance?