What is a Safety Valve and How Does It Work?

A safety valve is a critical component in various industries, designed to prevent equipment failure due to excessive pressure. Its role cannot be overstated. According to the American Society of Mechanical Engineers (ASME), improper valve function can lead to catastrophic accidents, resulting in over $1 billion in damages annually. Thus, understanding how a safety valve operates is essential for safety management.

Dr. Emily Carter, a renowned safety valve expert, remarked, "The integrity of a safety valve is fundamental to operational safety." Her insights highlight the importance of regular maintenance and testing. Many industries rely on these devices, from oil and gas to manufacturing. Yet, despite their importance, improper installation remains a concern. Surprising statistics indicate that up to 25% of valves may fail during critical situations.

The effectiveness of safety valves is tied to their design and application. However, many users may overlook operational parameters, leading to malfunctions. Continuous education in this field is vital to mitigate risks. Understanding the specifics can drastically reduce the potential for failure. Focusing on safety valves ultimately ensures a safer working environment for everyone involved.

What is a Safety Valve? Definition and Key Functions

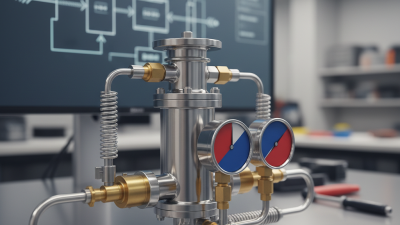

A safety valve is a critical component in various industries, designed to prevent overpressure scenarios. It acts as a mechanical device that automatically releases excess pressure from a system. This is essential in processes involving gases or liquids. By doing so, safety valves help protect equipment and prevent potential hazards. According to the National Board of Boiler and Pressure Vessel Inspectors, improper maintenance can reduce a safety valve’s effectiveness by up to 30%.

The key functions of a safety valve include opening at set pressures and closing once normal conditions are restored. This cycle is crucial in minimizing risks associated with system failures. Data from the American Society of Mechanical Engineers (ASME) indicate that improper sizing of safety valves is a common oversight. Nearly 40% of pressure relief incidents can be traced back to equipment miscalculations. These errors highlight a need for better training and adherence to standards.

Furthermore, many industries often neglect regular inspections. A survey noted that a staggering 65% of safety valves had not been checked within the recommended time frame. This neglect can lead to catastrophic failures and significant financial losses. Inadequate knowledge and implementation often result in critical gaps in safety protocols. Providing consistent awareness and education can address these shortcomings and enhance safety standards across the board.

What is a Safety Valve and How Does It Work?

| Dimension | Description |

|---|---|

| Definition | A safety valve is a device that automatically releases pressure from a boiler, pressure vessel, or other system to prevent its pressure from exceeding a predetermined set level. |

| Key Function | To maintain safe operating conditions by opening to release excessive pressure and then closing when normal conditions are restored. |

| Common Applications | Used in steam boilers, pressure relief systems, and various industrial applications where pressure control is necessary. |

| Normal Operating Pressure | Typically set based on the design and operational requirements of the system, ensuring safe limits are maintained. |

| Materials Used | Commonly made from metals such as stainless steel or brass to withstand high pressure and temperature environments. |

Historical Development of Safety Valves in Industrial Applications

Safety valves have a rich history in industrial applications. Originating in the 17th century, they were designed to prevent excessive pressure build-up in steam boilers. Early designs were rudimentary. However, they quickly became essential for safe operation in various industries. According to a recent report by the American Society of Mechanical Engineers, about 80% of industrial accidents involve equipment failure due to pressure issues. This highlights the need for effective safety valve integration.

In the 19th century, advancements in engineering led to the development of more reliable safety valves. The introduction of spring-loaded valves allowed for precise control of pressure release. This revolutionized steam systems and improved safety. Modern safety valves are subject to strict regulations. They must meet specific industry standards to ensure optimal performance.

**Tip:** Regularly inspect and maintain safety valves to prevent malfunctions. A minor oversight can lead to significant risks. Operators must be aware of potential signs of wear. Also, consider training sessions for employees on safety valve operation.

The future of safety valve technology looks promising. Innovations in materials and design are on the horizon. However, some industries still rely on outdated equipment. This can raise serious safety concerns. Continuous improvement should be a priority for all industrial sectors.

Common Types of Safety Valves and Their Specific Uses

Safety valves play a crucial role in various industries, ensuring equipment operates safely under pressure. There are different types of safety valves, each tailored to specific applications. For instance, spring-loaded safety valves are commonly found in steam and gas systems. They can accurately release excess pressure without causing equipment failure. A recent industry report states that these valves account for over 60% of safety valve usage in industrial settings.

Another type is the pilot-operated safety valve. This design offers higher accuracy and is commonly used in oil and gas sectors. It functions well even under varying pressure levels. According to industry data, pilot-operated valves achieve a 95% efficiency rate in preventing overpressure incidents. However, these valves require careful maintenance. Neglecting maintenance can lead to failure during critical situations, highlighting the need for regular checks.

Safety valves designed for different industries have unique applications. For instance, rupture discs are employed in chemical processing for their rapid response to pressure spikes. They are ideal for high-temperature scenarios but may not be reusable. This limitation raises questions about cost-effectiveness over time. Each type has its pros and cons, making it essential for engineers to select the right valve based on specific operational needs.

Working Principles: How Safety Valves Operate Under Pressure

Safety valves are critical components in pressure systems. They protect equipment from overpressure conditions. When pressure builds beyond a set limit, the valve opens. This release of pressure prevents potential disasters. The mechanism is simple yet effective. A spring holds the valve closed until pressure exceeds its capacity.

When the pressure rises, the valve responds rapidly. Fluid flows out, reducing the pressure instantly. The spring pressure is carefully calibrated. It ensures that the valve only opens at the designed threshold. Sometimes, the valve may not function as intended. This can lead to dangerous situations. Regular maintenance and inspection are essential.

The design of safety valves varies. Some have a poppet design, while others use diaphragm mechanisms. Each type serves the same purpose but operates differently. Understanding these differences is important. It helps in selecting the right valve for specific applications. Regular checks and balancing are necessary to ensure reliability.

Industry Standards and Regulations Governing Safety Valve Performance

Safety valves play a crucial role in maintaining system integrity and preventing overpressure. They must comply with specific industry standards and regulations. These guidelines ensure that safety valves operate effectively and reliably under varying conditions.

Organizations such as the American Society of Mechanical Engineers (ASME) set forth standards that dictate how safety valves must be manufactured and tested. Adherence to these standards is essential to guarantee performance and safety. Not all valves meet these criteria, which can lead to failures in critical systems. Regular inspections and maintenance are necessary to identify potential issues.

Testing methods also vary across industries. Some sectors require rigorous testing for every valve before installation. Other industries might allow less stringent measures. This disparity can lead to significant safety risks. Companies must make thoughtful decisions about their safety protocols to prevent mishaps. Balancing costs and safety is often a challenging task that requires ongoing reflection and improvement.

Related Posts

-

2026 How to Choose the Right Safety Relief Valve for Your System?

-

Top 5 Relief Valve Options for Optimal Pressure Control in Industrial Applications

-

The Best 10 Pressure Control Valve Models for Optimal Performance?

-

Top 10 Benefits of Using a Pressure Regulator Why You Need One?

-

Why You Need a Natural Gas Shut Off Valve for Home Safety and Maintenance

-

How to Choose the Right Pressure Control Valve for Your Needs?