What is a Pressure Regulator and How Does it Work?

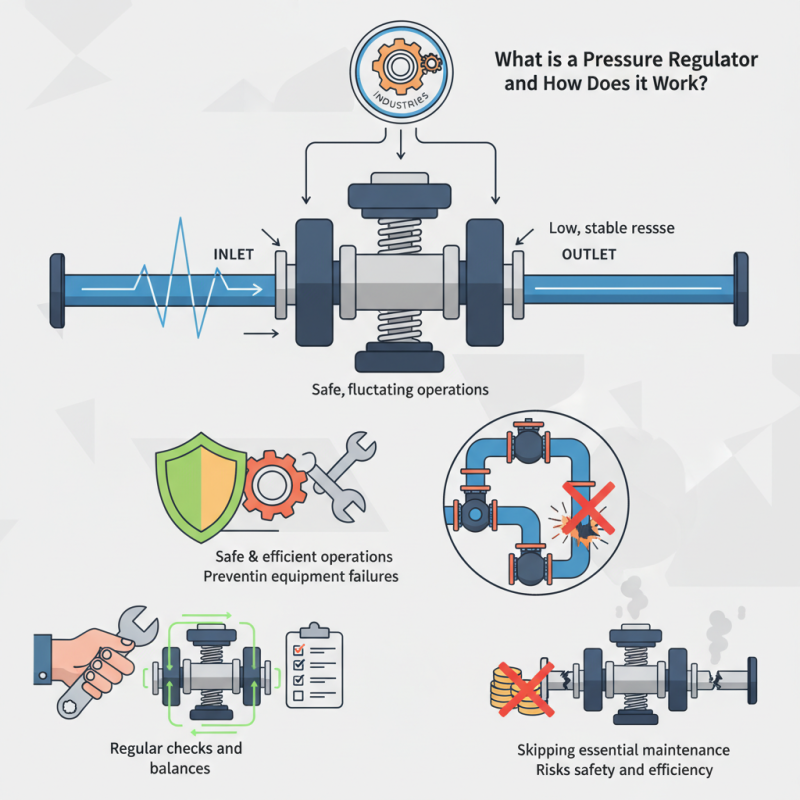

A pressure regulator is an essential device in many industries. It ensures the proper flow and pressure of gases and liquids. "A pressure regulator is crucial for safe and efficient operations," says Dr. John Thorne, a leading expert on fluid dynamics. His insight emphasizes the importance of understanding how these devices function.

Properly managing pressure can prevent equipment failures. A pressure regulator controls and maintains outlet pressure, protecting systems from pressure fluctuations. These devices prevent over-pressurization, which could lead to dangerous situations. Yet, the complexity of different systems often raises questions about their reliability.

Many users may overlook the maintenance required for pressure regulators. Neglecting this aspect can lead to performance issues or even accidents. Regular checks and balances are necessary. However, some companies skip essential maintenance to save costs. In doing so, they may risk safety and efficiency in their operations. Understanding the role of a pressure regulator is vital for anyone involved in handling such systems.

What is a Pressure Regulator?

A pressure regulator is a crucial device used to manage pressure in various systems. It ensures that the pressure remains at a safe and consistent level. This device is essential in applications ranging from gas distribution to hydraulic systems. By controlling pressure, it protects equipment and maintains efficiency.

Pressure regulators come in different designs. Some use springs and diaphragms. Others may use electronic controls. The basic principle remains the same: reduce high incoming pressure to a lower, usable level. This adjustment prevents potential damage. However, not all pressure regulators perform perfectly. Over time, wear and tear can affect their reliability. Regular maintenance and checks are necessary to ensure they function correctly.

Understanding how a pressure regulator works is vital. It is not just about adjusting pressure; it is about safety and efficiency. Users should be aware of their limitations too. Miscalculations or neglecting maintenance can lead to failures. This highlights the importance of education and awareness in using pressure regulators effectively.

Pressure Regulator Performance Analysis

This chart displays the performance metrics of a pressure regulator. The input pressure is measured in psi, the output pressure is reduced, and the flow rate is also provided in gallons per minute (GPM). Additionally, it shows the adjustment time in seconds and failure rate in percentage, illustrating the efficiency and reliability of the pressure regulating system.

The Importance of Pressure Regulation in Various Systems

Pressure regulation plays a critical role in various systems, ensuring efficiency and safety. In industrial settings, improper pressure levels can lead to equipment failure. According to a report by the American Society of Mechanical Engineers, nearly 30% of machinery downtime is due to pressure-related issues. This highlights the need for precise pressure control.

In residential systems, pressure regulators help maintain consistent water flow. A study showed that systems without adequate regulation can waste up to 20% more water. This inefficiency not only impacts utility bills but also creates unnecessary strain on plumbing. The importance extends to gas distribution, where too much pressure can lead to leaks or explosions.

Pressure regulation is not foolproof. Many systems still face challenges. Aging infrastructure can lead to inconsistent pressure levels. Regular maintenance is essential but often overlooked. Data shows that 40% of facilities do not adhere to proper inspection schedules. This neglect can result in serious safety hazards and increased operational costs. Reflecting on these issues is crucial for improving system reliability.

How Pressure Regulators Function: A Step-by-Step Overview

Pressure regulators play a critical role in various systems, managing the flow and pressure of gases or liquids. They maintain consistent output pressure, regardless of input fluctuations. This function is crucial in applications ranging from industrial processes to home appliances. According to industry reports, improper pressure levels can cause equipment damage, leading to costly repairs.

How do pressure regulators work? First, they sense incoming pressure through a diaphragm. Next, the diaphragm moves in response to changes, adjusting an outlet valve. This process ensures that the downstream pressure remains stable. For instance, in gas distribution networks, regulators manage pressures to avoid leaks or bursts. A report by the American National Standards Institute indicates that nearly 30% of gas leak incidents can be prevented with proper regulation.

**Tips:** Regular maintenance of pressure regulators can enhance their efficiency. Inspect for leaks or wear regularly. Understanding pressure ratings can facilitate better choices in selecting a regulator. Remember, not all systems require the same pressure levels. Adjusting settings is a step that requires caution. Mistakes can lead to significant issues. Always consult with a professional when in doubt.

What is a Pressure Regulator and How Does it Work?

| Feature | Description | Applications |

|---|---|---|

| Function | Regulates the pressure of gases or liquids to a desired level. | Used in HVAC systems, water supply systems, and gas distribution. |

| Types | Spring-loaded diaphragm, electronic, and pilot-operated regulators. | Various industrial, commercial, and residential applications. |

| Benefits | Improves safety, reduces wear on equipment, and enhances efficiency. | Used in oil and gas, chemical processing, and food & beverage industries. |

| Maintenance | Regular inspections, cleaning, and calibration are recommended. | Essential for reliable operation in critical systems. |

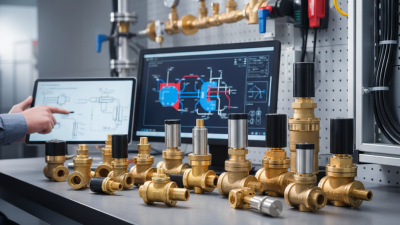

Types of Pressure Regulators and Their Applications

Pressure regulators are essential devices in various industries. They ensure a stable and safe pressure for gases and liquids. Different types of pressure regulators serve unique purposes, and understanding these types is crucial.

One common type is the gas pressure regulator. This type is widely used in residential and commercial gas systems. According to a report by the Gas Technology Institute, over 70% of new gas installations utilize these regulators. Their primary function is to reduce the high pressure from gas pipelines to a safe level for appliances.

Another type is the hydraulic pressure regulator, commonly used in industrial applications. These regulators maintain a specific pressure in hydraulic systems. They help optimize performance and ensure safe operations. The Hydraulic Institute reports that implementing these regulators can increase system efficiency by 15%.

Tips: Always check the compatibility of the regulator with your system. Regular maintenance is key. Failure to do so can lead to unexpected pressure fluctuations.

Choosing the right pressure regulator can be challenging. It often requires careful assessment of pressure needs and system demands. If unsure, consulting industry professionals can save time and resources.

Common Issues and Maintenance Tips for Pressure Regulators

Pressure regulators play a crucial role in various systems by controlling fluid or gas pressure. However, they can encounter several common issues that require attention. A recent industry report indicates that nearly 30% of pressure regulator failures stem from dirt and contaminants. Regular maintenance is essential to prevent these particles from clogging the internal components.

Another frequent issue is the wear of seals and diaphragms. Studies show these parts can degrade over time, leading to leaks and pressure inaccuracies. Checking for leaks regularly can help identify problems early. Using a pressure gauge can also facilitate monitoring. Adjusting the pressure settings improperly can lead to malfunctions. Always refer to standard guidelines when setting these parameters to avoid errors.

Routine inspection is fundamental in mitigating downtime. Many factors such as temperature and operational conditions influence the lifespan of a pressure regulator. Neglecting to check these can lead to unexpected failures. While maintenance may seem tedious, it significantly enhances reliability. Taking the time to perform these checks can save you from costly repairs.

Related Posts

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

Why You Should Choose the Right Gas Valve for Your Home Safety

-

How to Choose the Right Asco Solenoid Valve for Your Application

-

Top 5 Relief Valve Options for Optimal Pressure Control in Industrial Applications

-

Maximizing Efficiency with Asco Solenoids in Modern Automation Systems

-

How to Choose and Install a Water Pressure Relief Valve for Your Home