How to Optimize Valve and Automation Systems for Maximum Efficiency

In the pursuit of enhanced operational efficiency within industrial processes, the optimization of valve and automation systems stands as a critical focus area. Renowned expert in the field, Dr. Emily Carter, emphasizes, “The integration of advanced valve and automation technologies can significantly reduce energy consumption and improve overall system performance.” Her insights highlight the essence of leveraging cutting-edge methods and tools to streamline processes, thereby enabling industries to not only meet but exceed their performance benchmarks.

As industries increasingly turn towards automation, the significance of optimizing valve systems becomes paramount. The right combination of technology and strategic implementation can lead to substantial improvements in both productivity and reliability. By adopting best practices in valve and automation management, organizations can minimize downtime, enhance equipment lifespan, and ensure safer operations, all while adhering to sustainability goals. This optimization journey challenges us to rethink traditional practices and embrace innovative solutions that pave the way for more efficient and responsive systems in the valve and automation landscape.

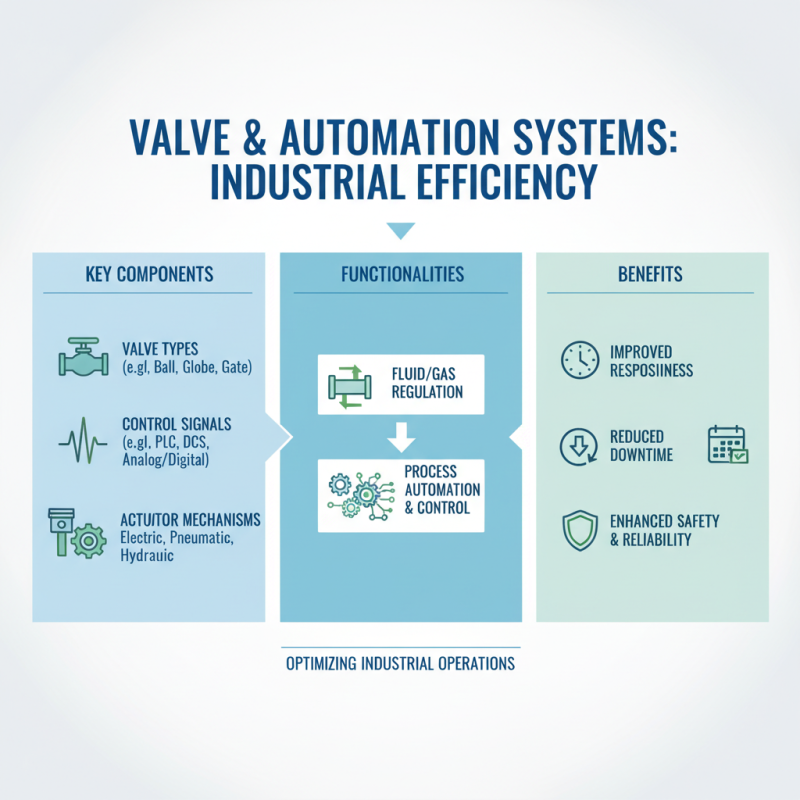

Understanding Valve and Automation Systems in Industrial Applications

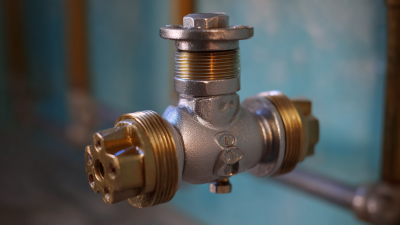

Valve and automation systems play a crucial role in enhancing operational efficiency within industrial applications. These systems regulate the flow of fluids and gases, allowing processes to run smoothly and safely. Understanding the various components and functionalities of these systems is essential for optimizing their performance. For instance, recognizing how valve types, control signals, and actuator mechanisms interact can lead to improved responsiveness and reduced downtime in industrial operations.

Tips: Regular maintenance checks on valves and automation systems can prevent unexpected failures. Implementing predictive analytics can also assist in monitoring system performance, enabling preemptive repairs before issues arise.

Furthermore, efficient valve selection is paramount. The right valve type ensures proper fluid dynamics while minimizing energy losses. Engaging in thorough process mapping can highlight areas where automation can further enhance efficiency. Automating control sequences not only reduces human error but also improves consistency, leading to higher quality outputs.

Tips: Ensure that automation software is updated regularly to leverage advancements in control strategies. Training staff on the latest technologies can also maximize the benefits of these systems, fostering a work environment geared towards continuous improvement.

Key Factors Influencing Efficiency in Valve Operations

Efficiency in valve operations can be influenced by several key factors, primarily focusing on design, maintenance, and control strategies. Firstly, the design of valves plays a critical role in determining operational efficiency. Selecting the appropriate valve type based on the fluid characteristics and operational conditions—such as temperature, pressure, and flow rate—ensures optimal performance. Additionally, employing advanced materials resistant to corrosion and wear can enhance longevity and reduce maintenance needs, thereby increasing overall system efficiency.

Secondly, regular and proactive maintenance is essential for sustaining efficient valve operations. Implementing a structured maintenance schedule including inspections, repairs, and replacements can prevent unexpected failures that lead to downtime and inefficiencies. Predictive maintenance techniques, leveraging data analytics and monitoring technologies, can further optimize maintenance efforts by addressing potential issues before they escalate into significant problems.

Control strategies also significantly influence valve efficiency. Employing intelligent automation systems that utilize real-time data can enhance decision-making processes related to flow regulation and pressure control. Such systems can adjust valve positions dynamically, ensuring optimized performance while minimizing energy consumption and wear. By harmonizing design, maintenance, and control approaches, organizations can achieve greater efficiency in their valve operations.

How to Optimize Valve and Automation Systems for Maximum Efficiency - Key Factors Influencing Efficiency in Valve Operations

| Factor | Description | Impact on Efficiency (%) | Recommended Action |

|---|---|---|---|

| Flow Rate Control | Maintaining optimal flow rate through appropriate valve sizing and selection. | 15 | Implement flow rate monitoring systems. |

| Regular Maintenance | Routine inspections and servicing of valves to prevent leaks and failures. | 20 | Establish a maintenance schedule. |

| Automation Integration | Incorporating automated controls for real-time adjustments and monitoring. | 25 | Utilize smart valve actuators and controls. |

| Material Selection | Choosing the right materials to withstand process conditions and reduce wear. | 10 | Evaluate materials based on environmental factors. |

| Training Personnel | Ensuring operators are well-trained in valve operation and troubleshooting. | 5 | Conduct regular training sessions and workshops. |

Best Practices for Maintenance and Inspection of Valves

Proper maintenance and inspection of valves are critical components in optimizing valve and automation systems for maximal efficiency. According to a recent report by the Valve Manufacturers Association, up to 25% of valve failures can be attributed to inadequate maintenance and inspection practices. Regularly scheduled inspections can help identify wear and tear, allowing for timely interventions to prevent catastrophic failures which could lead to costly downtimes.

One of the best practices for valve maintenance is implementing a predictive maintenance strategy. By utilizing advanced diagnostic tools, operators can monitor valve performance in real-time, predicting when maintenance is needed before a malfunction occurs. This approach can improve reliability, with studies showing a reduction in maintenance costs by up to 30%.

Tips: Always maintain detailed records of valve inspections and maintenance activities. This not only assists in recognizing patterns but also ensures compliance with safety regulations. Additionally, involve your team in regular training sessions to keep them informed about the latest technologies in valve inspection, fostering a culture of proactive rather than reactive maintenance. Frequent assessments coupled with continuous education can significantly enhance your systems' efficiency and longevity.

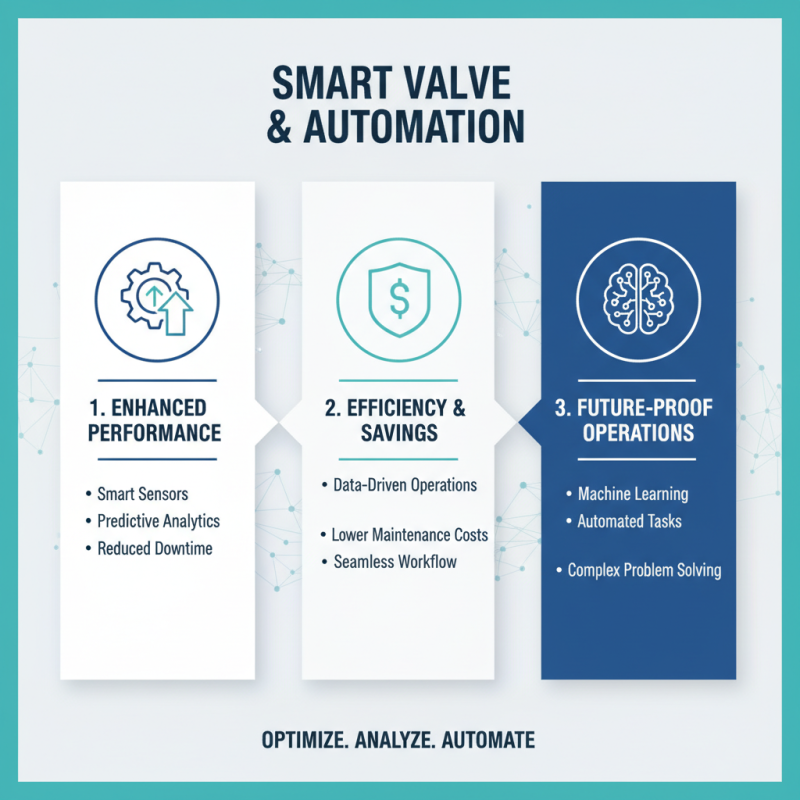

Advanced Technologies for Enhancing Automation Performance

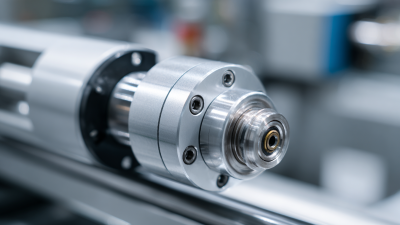

In the pursuit of optimizing valve and automation systems, leveraging advanced technologies is essential for enhancing performance and efficiency. The integration of smart sensors and predictive analytics allows operators to monitor system performance rigorously and mitigate potential issues before they escalate. These technologies enable a data-driven approach to operations, significantly reducing downtime and maintenance costs while ensuring a seamless workflow. Additionally, the adoption of machine learning algorithms can help automate routine tasks, thereby freeing up valuable human resources for more complex problem-solving initiatives.

Tips for maximizing your automation system's efficiency include regularly updating software and firmware to take advantage of the latest features and security improvements. Invest in training for your staff to ensure they are equipped with the knowledge to utilize advanced technologies effectively. Moreover, conducting periodic assessments of system performance can reveal inefficiencies that may be addressed through process adjustments or equipment upgrades.

As automation systems evolve, incorporating IoT devices can offer real-time connectivity and insights into operational performance. By utilizing cloud-based platforms, operators can access valuable data analytics from anywhere, enabling quicker decision-making and responsiveness to changing operational demands. Combining these advanced technologies with traditional systems can significantly streamline operations and enhance the overall reliability of valve and automation processes.

Strategies for Integrating Smart Systems with Valve Operations

Integrating smart systems with valve operations is crucial for maximizing efficiency within industrial processes. Smart automation technologies not only enable real-time monitoring of valve functions but also facilitate advanced data analytics. By employing predictive maintenance algorithms, organizations can foresee potential failures, thus minimizing downtime and enhancing operational reliability.

Tips: Begin by assessing the current infrastructure to identify integration opportunities. Employ IoT sensors on valves to gather data and feed it into a centralized system. This approach allows for enhanced visibility into valve performance, ensuring timely interventions when issues arise.

Furthermore, implementing artificial intelligence (AI) in valve control systems can optimize flow rates and reduce energy consumption. AI algorithms can analyze historical data and adjust operations dynamically to meet changing demand patterns. Smart control systems, when effectively utilized, chart a path towards energy conservation and cost efficiency.

Tips: Train staff on the benefits and functionalities of smart systems. Continuous learning ensures that your team can manage and maximize the use of these advanced technologies. Regularly revisit your automation strategies and upgrade them to keep pace with technological advancements, ensuring sustained efficiency improvements.

Optimizing Valve and Automation Systems for Maximum Efficiency

Related Posts

-

How to Choose the Right Valve and Automation Solutions for Your Industry Needs

-

How to Choose the Right Automatic Valve for Your Industrial Needs

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

Top 10 Benefits of Using Automatic Valves in Industrial Applications

-

Maximizing Efficiency with Asco Solenoids in Modern Automation Systems

-

Why You Should Choose the Right Gas Valve for Your Home Safety