What is a Natural Gas Valve and How Does It Work?

Natural gas valves play a critical role in ensuring the safe and efficient use of natural gas across various industries. According to a report by the International Energy Agency, natural gas consumption is projected to rise by over 40% by 2040, emphasizing the importance of reliable control systems. A natural gas valve controls the flow and pressure of gas within pipelines and appliances, acting as a safeguard against leaks and explosions.

Industry expert Dr. Jane Holtzmann states, "The reliability of natural gas valves is paramount in preventing accidents." Her insights highlight the necessity for regular maintenance and inspection. Despite advances in technology, failures still occur. The consequences of faulty valves can be severe, impacting both safety and operational costs. For operators, understanding the mechanics of a natural gas valve becomes vital for promoting safety and efficiency in gas distribution systems.

As the global energy landscape evolves, so too must our understanding of natural gas valves. This shift invites reflection on how the industry can improve valve technology and maintenance practices. Addressing these challenges will be crucial in meeting future energy demands while ensuring safety and sustainability.

What is a Natural Gas Valve?

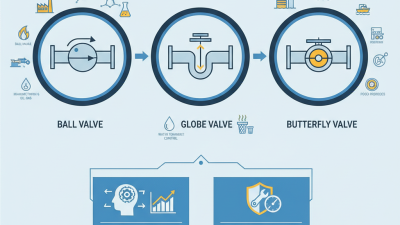

A natural gas valve is a crucial component in gas distribution systems. It regulates the flow of natural gas from pipelines to various appliances. These valves can be found in homes, industries, and power plants. Their main function is to ensure a safe and efficient gas supply.

These valves come in various types and designs. A common type is the shut-off valve. This valve allows users to stop gas flow completely during maintenance tasks. Another kind is the control valve, which adjusts gas pressure as needed. Both types are vital for safety and functionality.

However, improper installation or maintenance can lead to issues. Sometimes, these valves malfunction. This can cause gas leaks or safety hazards. It is important to check them regularly. Neglecting this can have serious consequences. People often overlook the role of these valves until a problem arises.

What is a Natural Gas Valve and How Does It Work?

| Feature | Description |

|---|---|

| Function | Control the flow of natural gas in pipelines and appliances. |

| Types | Manual valves, automatic valves, safety valves, and solenoid valves. |

| Materials | Typically made from brass, stainless steel, or plastic. |

| Operation Mechanism | Can be manually operated or actuated through electronic signals in automated systems. |

| Safety Features | May include pressure relief systems and automatic shut-off capabilities. |

| Applications | Used in residential, commercial, and industrial settings for heating and cooking. |

Types of Natural Gas Valves and Their Uses

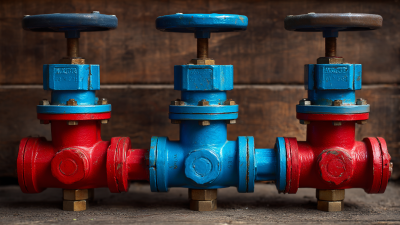

Natural gas valves play a crucial role in the safe and efficient distribution of natural gas. There are several types of valves, each tailored for specific functions. Gate valves, for instance, are commonly used to start or stop the flow entirely. They are simple, effective, and ideal for on/off service. Meanwhile, ball valves provide quick shut-off capabilities, making them popular in various applications. According to industry data, ball valves are favored in over 60% of installations due to their durability and reliability.

Another essential category is the control valve. Control valves adjust flow rates according to system requirements. They help maintain pressure points and regulate temperature. A recent study indicated that the global market for control valves is expected to reach $10 billion by 2025. Additionally, safety valves are critical components designed to prevent pressure accumulation. They automatically release gas when safety thresholds are crossed. Unfortunately, improper installation or maintenance of these valves can lead to safety hazards.

These diverse types ensure that natural gas systems operate smoothly. Yet, it’s concerning that many operators overlook regular inspections. Inadequate attention could result in potential failures or leaks—issues that can be costly. Maintaining valves requires diligence and an understanding of specific needs. Each type serves a purpose, but reality shows gaps in awareness and training in many settings.

Natural Gas Valve Types and Their Usage Frequency

How Natural Gas Valves Function Mechanically

Natural gas valves play a crucial role in managing gas flow within pipelines and appliances. These devices control the pressure and volume of gas that passes through systems. Mechanical components, like diaphragms and seals, are vital for their operation. According to the American Gas Association, up to 98% of natural gas pipelines utilize some form of valve technology. That percentage highlights the importance of reliability in these mechanisms.

When a gas valve is activated, it either opens or closes based on pressure signals from the system. This action often involves a diaphragm that moves in response to changes in pressure. A study from the National Association of Regulatory Utility Commissioners indicates that improperly functioning valves can lead to safety hazards. Inadequate maintenance may result in pressure build-up, causing leaks or failures. Such risks emphasize the need for regular inspections and adherence to safety protocols.

Interestingly, many choose to overlook their valve maintenance until issues arise. Operators should examine valves every six months to ensure optimal performance. Simple adjustments can make a significant difference in safety and efficiency. As technologies evolve, so do the challenges in maintaining natural gas valves. Keeping pace with innovations can be daunting, yet essential for those in the industry.

Installation and Maintenance of Natural Gas Valves

Natural gas valves are essential components in gas distribution systems. Proper installation and maintenance are crucial for safety and efficiency. According to a report by the American Gas Association, improper valve installation can lead to serious leaks and gas losses that cost millions annually. Following the correct procedures helps prevent these issues.

When installing a natural gas valve, ensure it is placed in an accessible location. This allows for easier maintenance and inspection. Use appropriately rated fittings to avoid leaks. Always check local regulations to comply with safety standards. A pressure test after installation is essential. This ensures there are no leaks before the system goes live.

Tip: Regularly inspect your valves for signs of wear or damage. Even small issues can escalate over time. A maintenance schedule is vital for long-term performance. Be vigilant and address potential problems early. Always consult with a qualified technician for repairs. This can save time and ensure the safety of your gas system. Remember, neglected valves can lead to unsafe conditions.

Safety Considerations and Regulations for Natural Gas Valves

Natural gas valves play a crucial role in controlling gas flow. However, safety should be the priority when dealing with them. These valves need to comply with regulations to ensure proper functionality. Each valve type is designed with specific safety features. For instance, automatic shut-off valves can prevent leaks during malfunctions.

Regular maintenance of natural gas valves is essential. Complications can arise if these valves are neglected. Routine checks can identify wear and tear early. Missing these checks may lead to unsafe situations. Operators must recognize the importance of following guidelines set by regulatory bodies.

In some cases, safety training may be lacking. This creates gaps in knowledge about emergency procedures. A lack of understanding can be dangerous. Ensuring all personnel are properly trained is vital for safe operations. Awareness of potential hazards can significantly reduce risks associated with natural gas valves.

Related Posts

-

Understanding Natural Gas Valves: Essential Guide to Safety and Efficiency in Your Home

-

Exploring the Future of Valve Automation and Control in Sustainable Energy Solutions

-

10 Essential Tips for Selecting the Right Control Valve for Your System?

-

Top Electric Valves Types and Their Applications in Modern Industry?

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

Understanding Pressure Relief Valves: Key Specifications and Their Crucial Role in Industrial Safety