What is a gas shut off valve and how does it work?

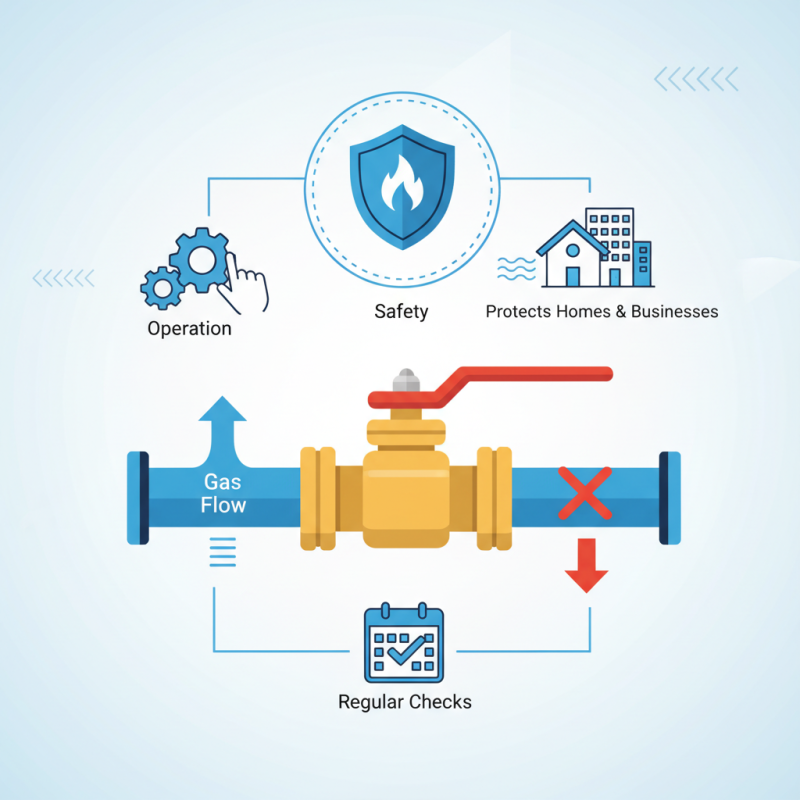

A gas shut off valve is an essential component in any gas distribution system. It ensures safety by controlling the flow of gas. This valve can stop or regulate gas supply, preventing leaks or dangerous situations. When installed correctly, it protects homes and businesses from potential hazards.

The operation of a gas shut off valve is straightforward. The valve can be turned by hand or automatically in emergencies. It responds quickly, cutting the gas supply immediately. However, it is vital for users to understand how to operate it. Many people may not know its location or how to use it effectively.

Having a gas shut off valve installed is a proactive safety measure. Yet, it requires regular checks. Over time, these valves can wear out or malfunction, leading to safety risks. It's important to reflect on how often maintenance is performed. Regular inspections ensure the valve works when it matters most.

What is a Gas Shut Off Valve?

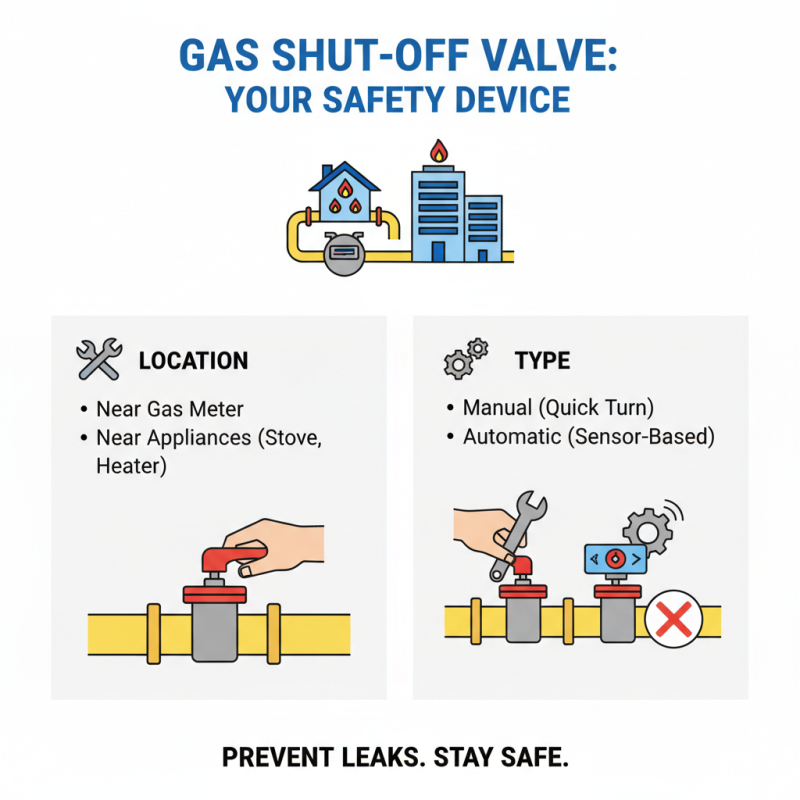

A gas shut off valve is a crucial safety device used in homes and businesses. Its primary function is to stop the flow of gas in case of a leak, helping to prevent dangerous situations. These valves are often found near gas meters or appliances such as stoves and heaters. They can be manually operated or automatic. Manual valves require a quick turn to close, while automatic valves respond to certain sensors.

When using a gas shut off valve, it's important to know how it functions. You might encounter different types: ball valves and gate valves are common. Ball valves offer a quick shut-off, while gate valves are more gradual. Not all valves operate the same way, so familiarize yourself with the type in your space. Consider marking the valve with clear labels.

**Tips:** Regularly test your valve to ensure it's functional. Turn it off and on occasionally. Check for any gas odors nearby. If you smell gas, evacuate the area and call for help immediately. It's better to be safe than sorry. Understanding where your gas shut off valve is located can be life-saving.

Types of Gas Shut Off Valves

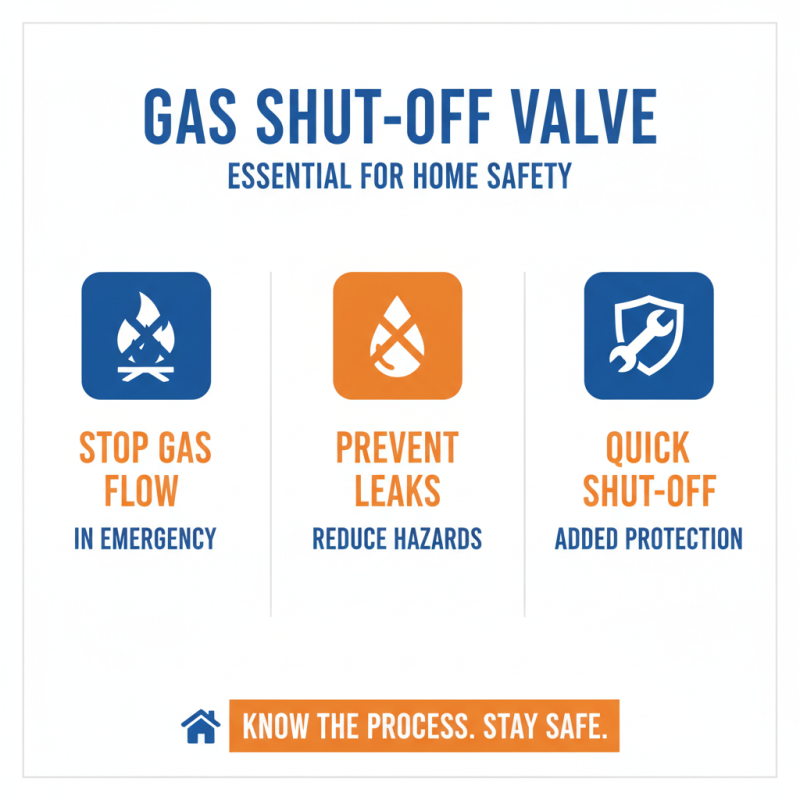

Gas shut off valves are crucial for safety in homes and businesses. They control the flow of gas in pipelines and systems. Without them, leaks can occur, leading to hazardous situations. Understanding the different types of gas shut off valves is important for effective usage and maintenance.

There are several types of gas shut off valves. Ball valves are popular for their ease of use. They allow for quick shut off and precise control. Butterfly valves are another option, often used in larger systems. These valves can be more complex but provide significant flow control. Each type has its specific benefits and drawbacks.

In some cases, automatic shut off valves are installed. They activate during emergency situations, shutting off the gas automatically. This can be vital in protecting property and lives. Selecting the right valve can be challenging. Each situation requires careful consideration of safety needs and system design. Proper maintenance is essential too. Neglecting it may lead to failure over time. Attention to details can prevent dangerous incidents.

Gas Shut Off Valve Types and Their Functionality

How Gas Shut Off Valves Function

Gas shut-off valves are crucial safety devices in modern homes. They are designed to stop the flow of gas in case of emergencies or leaks. Understanding how they work can help homeowners prevent disasters. A typical gas shut-off valve operates using a simple mechanism. When the handle is turned, it opens or closes the valve. This action interrupts the gas supply, either allowing it to flow or stopping it completely.

Installation and placement matter. A valve should be easily accessible but not in a high-traffic area. If it’s out of reach or hidden, it could be hard to use in a crisis. Regular checks on the valve's condition are essential. Corrosion or damage can render it ineffective. Homeowners often overlook this, which can lead to unsafe situations. The valve must work smoothly in emergencies.

Understanding the function of these valves can be challenging. Some might not realize that they need to be manually operated. It’s not just a safety feature that works on its own. Educating family members about its use is critical. Practice turning it off safely so everyone knows what to do. Being prepared is key to ensuring safety at home.

Installation Process for Gas Shut Off Valves

Installing a gas shut off valve is essential for safety. This valve allows you to stop gas flow quickly in case of an emergency. It can prevent leaks and other potential hazards. Understanding the installation process is crucial for anyone considering this important safety measure.

Start by gathering the necessary tools: a wrench, pipe thread sealant, and a pipe cutter. Ensure the gas supply is turned off before beginning. Measure the pipe where the valve will be installed and cut it carefully. It’s vital to apply the pipe thread sealant on the threads to ensure a tight fit. Place the valve in the correct direction, matching the flow of gas. After securing it, double-check your work.

Testing is a critical step in the installation process. Once everything is set, turn the gas supply back on slowly. Check for leaks using soapy water. Bubbles will form if there is a leak. If everything checks out, you’re ready for use. However, make sure to reflect on the importance of regular maintenance for the valve. It’s easy to forget, but it’s crucial for continued safety.

Maintenance Tips for Gas Shut Off Valves

Gas shut off valves are vital for safety in homes with gas appliances. Regular maintenance can prevent costly issues. First, check the valve regularly for signs of wear. Look for rust or corrosion. These can indicate it's time for replacement. A worn valve may not close properly.

It's also important to test the valve's operation. Turn it off and on every six months. This ensures it functions properly when needed. If you hear any hissing sounds, shut it off and call a professional. Small leaks can escalate quickly.

Consider labeling the valve for easy access. This helps in emergencies. Don’t wait until there’s a problem to act. Schedule a professional inspection at least once a year. Being proactive can save you time and stress. Your safety is paramount.

What is a gas shut off valve and how does it work? - Maintenance Tips for Gas Shut Off Valves

| Aspect | Details |

|---|---|

| Definition | A gas shut off valve is a mechanical device that is used to stop the flow of gas in a system. |

| Function | It allows users to safely cut off gas supply for maintenance or in case of an emergency. |

| Types | Manual, automatic, solenoid valves. |

| Common Uses | Residential heating, appliances, commercial applications. |

| Maintenance Tips | Regularly check for leaks, ensure accessibility, lubricate moving parts, test functionality. |

| Signs of Failure | Unusual noises, difficulty operating, gas smell. |

Related Posts

-

Why You Need a Natural Gas Shut Off Valve for Home Safety and Maintenance

-

How to Locate and Use a Natural Gas Shut Off Valve Safely

-

Maximizing Efficiency with Asco Solenoids in Modern Automation Systems

-

How to Effectively Locate and Operate a Shut Off Valve in Your Home

-

Top 5 Asco Solenoid Applications and Benefits You Need to Know

-

Top 5 Relief Valve Options for Optimal Pressure Control in Industrial Applications