10 Essential Tips for Selecting the Right Control Valve for Your System?

Selecting the right control valve is crucial for any system. Control valves play a pivotal role in regulating flow and pressure. Choosing the wrong type can lead to inefficiency and higher costs. Each system has unique requirements. Understanding these needs is essential.

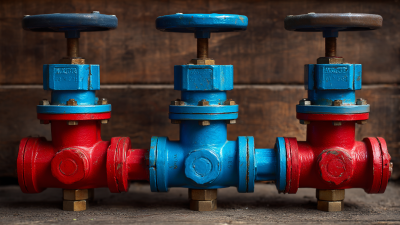

Consider different control valve types. Each type offers distinct advantages and disadvantages. For instance, globe valves are great for throttling, while ball valves provide quick shut-off. The choice can significantly affect system performance.

Don’t forget maintenance aspects. Some valves require more frequent upkeep than others. This could lead to unexpected downtime. Analyze your operational capacity. It's vital to choose a valve that fits both your technical and financial criteria. Taking time to reflect can prevent costly mistakes.

Understanding the Role of Control Valves in Fluid Systems

Control valves play a critical role in fluid systems. They help regulate flow, pressure, and temperature. By adjusting these parameters, control valves ensure optimal system performance. A poorly selected control valve can lead to operational inefficiencies. This often results in higher costs and potential system failures.

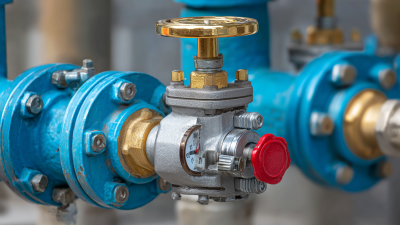

When choosing a control valve, consider the application and fluid characteristics. Is the fluid corrosive or non-corrosive? The valve material must match the fluid type. Size also matters. An oversized valve may result in poor control. An undersized valve can restrict flow, leading to pressure drops. Each detail is vital in making the right choice.

Moreover, the operating environment is crucial. Temperature extremes can affect valve performance. Regular maintenance is also required. A neglected valve may fail when needed most. It’s essential to inspect and test them regularly, despite the inconvenience. Ensuring the right control valve can save time and money in the long run. Yet, it’s easy to overlook such details. The implications could be significant.

Key Factors to Consider When Choosing Control Valves

Selecting the right control valve is crucial for system efficiency. Start by analyzing the specific application requirements. For instance, consider the fluid type and its properties. Fluids can be corrosive, viscous, or contain solids. According to a recent industry report, nearly 40% of valve failures are due to improper selection based on fluid characteristics.

Another key factor is the valve size. Choosing the correct size impacts flow rates significantly. An oversized valve can lead to instability. On the other hand, a valve that is too small can restrict flow and create pressure drops. A study shows that 25% of process inefficiencies stem from incorrectly sized valves. This often results in costly downtime and maintenance.

Lastly, think about the control method. Automation is increasingly vital in modern systems. Smart valves offer real-time data and improved response times. Yet, integrating automation can be complex. Many find that technology does not always yield expected results. This is an area for reflection and improvement in operational strategies.

Control Valve Selection Factors

This chart illustrates the importance levels of various factors to consider when selecting control valves. Each factor has been rated on a scale from 1 to 10 based on its significance in ensuring optimal operation within a control system.

Types of Control Valves and Their Applications

When selecting control valves, understanding the types and their applications is crucial. There are several common types of control valves. Each type serves a specific purpose. For instance, globe valves are ideal for throttling. They can manage flow rates effectively. On the other hand, ball valves offer quick shut-off capabilities. They are great for systems requiring immediate flow control.

Another type is the butterfly valve. These are often used in large piping systems. They regulate flow with minimal pressure drop. However, they may not be suitable for all applications. You must assess your needs carefully. Then there are check valves, which prevent backflow. They are essential for maintaining system integrity. Each valve type has its benefits and drawbacks. Make sure you consider these factors before making a decision.

In addition to valve types, the material choice matters. For corrosive media, choose materials that resist deterioration. That could mean stainless steel or specialized plastics. Sometimes, people overlook the importance of maintenance. Regular upkeep can extend the life of control valves. Neglecting this could lead to system failures. Thus, understanding both type and material is essential for effective selection.

10 Essential Tips for Selecting the Right Control Valve for Your System

| Tip No. | Tip Description | Valve Type | Typical Applications |

|---|---|---|---|

| 1 | Understand system requirements. | Ball Valve | Water systems, Gas flow control |

| 2 | Consider the flow characteristics. | Globe Valve | Liquid flow regulation, Throttling services |

| 3 | Assess pressure and temperature conditions. | Butterfly Valve | HVAC systems, Water distribution |

| 4 | Select the right material for the valve. | Check Valve | Protection in pipelines, Drainage systems |

| 5 | Evaluate actuator options. | Solenoid Valve | Automatic control systems, Hydraulic applications |

| 6 | Determine the required flow rate and CV. | Pinch Valve | Slurry transport, Bulk material handling |

| 7 | Account for environmental conditions. | Diaphragm Valve | Pharmaceuticals, Food and beverage |

| 8 | Consider maintenance and lifespan. | Multi-turn Valve | Instrumentation, Oil & Gas |

| 9 | Review control method and compatibility. | Electric Valve | Automated systems, Temperature control |

| 10 | Consult with a professional if needed. | Control Valve (Various Types) | Applicable across various industries |

Evaluating Sizing and Pressure Requirements for Control Valves

When selecting control valves, sizing and pressure requirements are crucial. Proper sizing ensures the valve can handle flow rates without issues. An undersized valve may cause noise or even damage. On the other hand, an oversized valve can lead to inefficiency. It's important to know your system's flow characteristics.

Pressure requirements also play a significant role. This includes both inlet and outlet pressure. High pressure can impact valve performance. You might need to consider pressure drop as well. If the drop is too great, it can lead to control problems. It's vital to assess your system's operating conditions and pressure profiles carefully.

Sometimes, even minor details make a difference. Use the valve manufacturer's guidelines as a reference. If you're unsure about your measurements, consult with experts. Mistakes in sizing or pressure evaluation can lead to costly revisions. Remember, every system is unique. Take the time to analyze your specific needs before making a decision.

Assessing Reliability and Maintenance Needs of Control Valves

When selecting control valves, understanding reliability and maintenance needs is crucial. Many systems fail due to inadequate valve maintenance. A study from the Control Valve Center shows that 50% of valve failures result from improper upkeep. Regular inspections and prompt repairs can enhance the lifespan of control valves significantly.

Tip: Assess the materials used in the valve construction. For corrosive environments, choose materials that resist degradation. This can lead to fewer maintenance issues in the long run.

Moreover, unexpected downtimes can result from overlooked maintenance schedules. A maintenance strategy should include routine checks. According to a report by Engineering.com, implementing a preventive maintenance plan can reduce overall maintenance costs by up to 30%.

Tip: Look into predictive maintenance technologies. These can monitor valve performance in real time. Indicators of wear and tear can help prevent potential failures before they occur. This proactive approach ensures efficiency and reliability. Keep in mind, though, that technology can fail or be misinterpreted, which adds a layer of complexity to the maintenance process.

Related Posts

-

2025 Top 5 Control Valve Trends Driving Efficiency in Industrial Applications

-

2025 Top Trends in Automatic Valves for Industry and Home Use

-

How to Optimize Valve and Automation Systems for Maximum Efficiency

-

Exploring ASCO Solenoids: The Backbone of Modern Automation in Industries

-

Understanding Natural Gas Valves: Essential Guide to Safety and Efficiency in Your Home

-

What is a Gas Shut Off Valve and Why You Need One for Your Safety