Top Electric Valves Types and Their Applications in Modern Industry?

Electric valves play a vital role in modern industrial applications. They are crucial in different sectors like manufacturing, oil and gas, and water treatment. These devices control the flow of liquids and gases efficiently. With automation and smart technology, electric valves have gained popularity. They offer precision and reliability in fluid control.

There are various types of electric valves available today. Each type serves specific applications. From simple on-off controls to complex modulating valves, the options are vast. Some industries rely heavily on electric valves for safety and efficiency. However, the choice of the right valve can be challenging.

Understanding the different electric valves and their functions is essential. This knowledge helps industries optimize their operations. It also raises questions about maintenance and potential failures. Proper selection is not always straightforward. In some cases, businesses might overlook crucial factors. This oversight could lead to inefficiencies or increased costs.

Types of Electric Valves: Overview of Key Variants in Industry Use

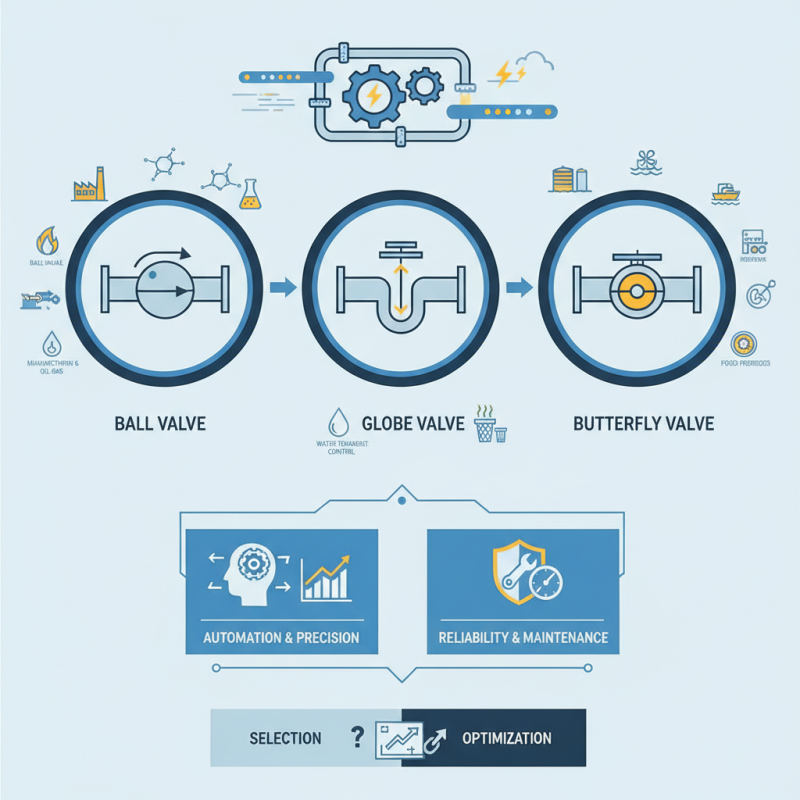

Electric valves play a vital role in various sectors, including water treatment, manufacturing, and oil and gas. They act as actuated valves that automate fluid control. Key variants of electric valves include globe valves, ball valves, and butterfly valves. These designs each serve unique functions across industries.

In the oil and gas sector, ball valves are particularly popular. Their quick opening and closing capabilities make them ideal for high-pressure applications. According to a recent industry report, the global ball valve market is expected to grow by 6.5% annually, reflecting increased demand for automation. Conversely, globe valves excel in flow regulation, offering precise control. However, they tend to have higher pressure drops, which may not suit all scenarios.

Butterfly valves are lightweight and cost-effective. They are commonly used in water treatment plants. However, they may struggle with high-pressure liquids compared to other types. Industry analysts note a shift towards more sophisticated designs. These will help address challenges like energy efficiency and maintenance costs. Electric valves are evolving rapidly, but there’s still room for improvement in reliability and responsiveness.更好的性能仍需在实践中探讨。

Key Features and Advantages of Electric Valves in Industrial Applications

Electric valves have gained popularity in various industrial settings due to their efficiency and reliability. These valves provide precise control over fluid and gas flow in pipelines. Their unique design allows for quick response times and minimal maintenance. This makes them suitable for industries like water treatment, oil and gas, and chemical processing.

One key feature of electric valves is their ability to integrate with automated systems. This leads to increased efficiency and reduced human error. Operators can monitor and adjust valve positions remotely, enhancing control. However, some might find the initial setup costs high. Additionally, power failures can impact system performance, which requires backup systems for reliability.

Moreover, electric valves offer a range of different types, each suited for specific applications. Butterfly valves are ideal for smooth flow rates and quick opening/closing. Meanwhile, ball valves are known for their leak-tight sealing abilities. Despite these advantages, the choice of the right electric valve can be complicated. Industry professionals must consider factors like fluid type, pressure, and temperature. This careful selection process is crucial for optimizing system performance.

Electric Valves in Process Control: Data-Driven Insights and Trends

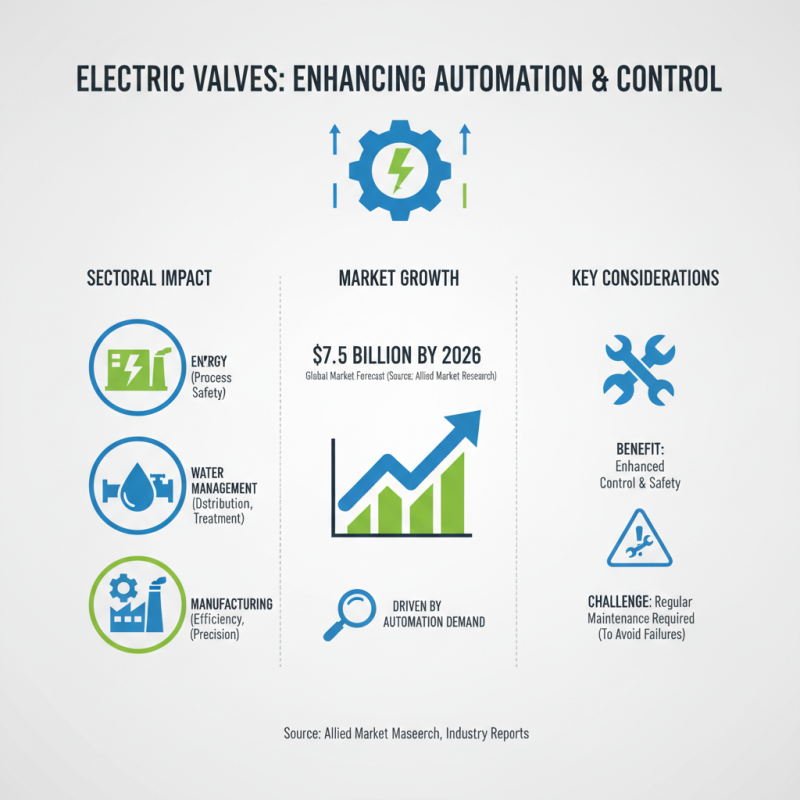

Electric valves play a crucial role in modern process control. Recent industry reports indicate that the global electric valve market is expected to grow significantly. A study projected an annual growth rate of 6.2% through 2025. This growth highlights the increasing demand for automation across various sectors.

In process control, electric valves are preferred for their precision. They allow for quick adjustments to flow rates and pressures. According to data from a leading analytical firm, over 45% of industries now implement smart control systems. This shift leads to improved efficiency and reduced operational costs. However, the adoption of these technologies can be challenging. Not every company is ready to invest in advanced systems.

Experts point out that while electric valves offer many benefits, they also present challenges. Proper calibration is essential for optimal performance. Inaccurate settings can lead to significant waste. Some industries must still rely on traditional methods due to budget constraints. Continuous training for personnel is vital. Only then can industries fully leverage the potential of electric valves.

Top Electric Valves Types and Their Applications in Modern Industry

Applications of Electric Valves in Energy, Water, and Manufacturing Sectors

Electric valves play a crucial role in various sectors, including energy, water management, and manufacturing. In the energy sector, for instance, electric valves enhance process control and safety. According to a report by Allied Market Research, the global electric valve market is expected to reach $7.5 billion by 2026, driven by the growing demand for automation. It is essential to note that the integration of these valves can pose challenges, such as the need for regular maintenance to avoid failures.

Water treatment facilities increasingly rely on electric valves for efficient flow control. They ensure the precise regulation of water distribution, essential for urban and industrial use. The World Health Organization emphasizes that over 2 billion people lack safely managed drinking water. Thus, optimizing water systems with advanced valves is a necessity. However, many facilities struggle with outdated systems, highlighting the need for continual upgrades and training.

In manufacturing, electric valves improve efficiency and reduce waste. Industries that use automated production lines benefit significantly from their application. However, some manufacturers still resist implementing these technologies. Concerns about upfront costs and technical skills hinder progress. As highlighted in the McKinsey report on Industry 4.0, embracing electric valves can significantly boost productivity. Yet, transitioning requires a shift in mindset and investment in employee training.

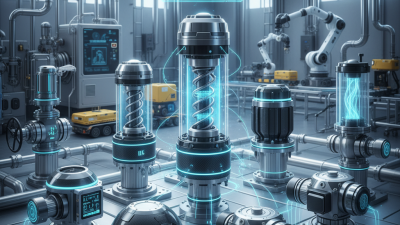

Future Developments: The Role of Smart Technology in Electric Valves

The integration of smart technology is transforming the electric valve landscape. Modern electric valves are now equipped with sensors and data analytics capabilities. These advancements offer real-time monitoring and control. Industries can now optimize processes and enhance efficiency. For instance, a factory can adjust valve settings based on live data, improving productivity.

However, the shift towards smart technology isn't without challenges. Reliability concerns often arise in critical applications. Potential system failures or data inaccuracies can lead to significant issues. Maintenance also becomes more complex and costly with sophisticated technology. Some systems may require specialized skilled technicians for repairs.

Despite these challenges, the benefits are compelling. Enhanced automation allows for greater precision in operations. Industries are investing in training to manage these advanced systems. The need for continuous improvement and adaptation remains essential. Smart technology in electric valves is not just a trend; it’s becoming a necessity in modern industry.

Related Posts

-

2025 Top 10 Valve Actuators Revolutionizing Industrial Automation with 25 Percent Efficiency Increase

-

10 Essential Flow Control Tips to Optimize Your Workflow and Productivity

-

Top 5 Asco Solenoid Applications and Benefits You Need to Know

-

Exploring the Benefits of Installing a Water Pressure Relief Valve in Your Home Plumbing System

-

Top 10 Benefits of Using Automatic Valves in Modern Plumbing Systems

-

Why You Need a Natural Gas Shut Off Valve for Home Safety and Maintenance