Digital Control Valve Tips for Optimal Performance and Efficiency?

In the world of industrial automation, achieving optimal performance and efficiency is essential. Control valves play a crucial role in this process. According to industry expert Dr. Jane Smith, "The right control valve can significantly improve system performance." Her insights highlight the importance of selecting and maintaining effective control valves.

Despite the advancements, many facilities still struggle with valve performance issues. Some managers overlook routine maintenance or fail to choose the right products. This negligence can lead to inefficiencies, increased costs, and system failures. For example, a poorly calibrated valve can cause pressure fluctuations, affecting overall productivity.

To enhance the performance of control valves, operators need to invest time in training and research. Understanding the specific requirements of their systems can lead to better decision-making. Even the best technology cannot compensate for a lack of knowledge. Control valves are vital, but they require attention to detail and ongoing evaluation to truly perform optimally.

Understanding the Basics of Digital Control Valves and Their Applications

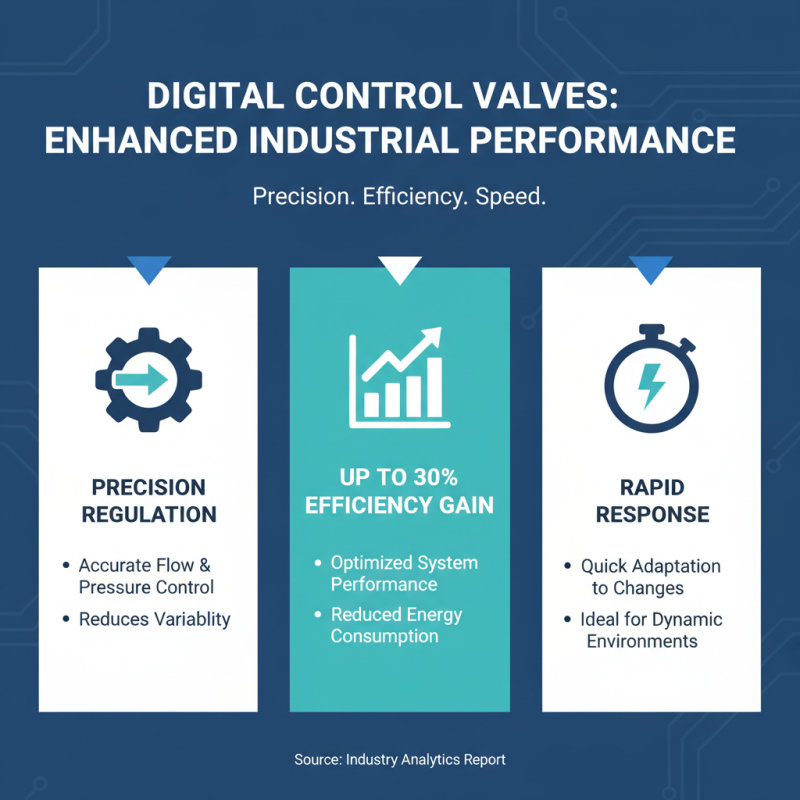

Digital control valves play a critical role in modern industrial applications. These valves regulate flow and pressure with precision, improving overall system performance. According to a recent report from industry analytics, digital control valves can enhance efficiency by up to 30% compared to traditional methods. Their ability to respond rapidly to changes makes them ideal for dynamic environments.

Understanding the basics is essential. Digital control valves consist of an actuator, sensors, and a control system. They communicate data in real-time, allowing for immediate adjustments. Many systems integrate these valves with advanced monitoring tools. They provide valuable insights into system performance and operational parameters. However, some facilities still rely on older technologies, missing out on efficiency gains.

Yet, not all implementations go smoothly. Common issues include misconfigurations and inadequate training. Users may overlook the importance of regular maintenance. This results in reduced functionality and increased downtime. Industry research highlights that improper setup can lead to performance drops of up to 25%. It’s crucial to evaluate your system’s needs and invest in proper training for operators.

Key Performance Metrics for Digital Control Valves in Industrial Settings

In industrial settings, key performance metrics for digital control valves play a crucial role. These metrics help to gauge efficiency and reliability. Commonly monitored factors include flow rate, pressure drop, and response time. Flow rate affects process consistency. An inconsistent flow can lead to product quality issues.

Pressure drop is equally important. If the pressure drop is too high, it can indicate blockages or malfunctions. This situation can lead to unnecessary downtime and increased costs. Monitoring these values regularly is essential. It allows for timely maintenance and parts replacement before bigger issues arise.

Response time is vital in dynamic processes. A delayed response may affect the entire system's performance. If a valve doesn't act quickly, it can disrupt operations. Regular calibration and testing can help maintain optimal response times. However, achieving perfect metrics is challenging. Each system is unique, and unexpected issues can arise. Continuous assessment and adjustments are necessary for true efficiency.

Best Practices for Optimizing Flow Control and Valve Response Time

Digital control valves are crucial in optimizing flow control and valve response time. A report by Flow Control indicates that proper tuning of the control loop can lead to a 20% increase in system efficiency. In many applications, response time is critical. Delays can lead to inefficiencies and potential damage. A study from the International Society for Automation highlights that an optimal response time improves process stability.

Selecting the right actuator is essential. It should match the valve type and service conditions. Many overlook this aspect. According to recent data, mismatched actuators can decrease valve performance by 30%. Maintenance routines are often neglected as well. Regular checks on the actuator and valve body can prevent larger failures. A report from the American Society of Mechanical Engineers suggests that planned maintenance can reduce downtime by 25%.

Final system tuning requires attention to detail. Many engineers find this step challenging. They may skip fine-tuning adjustments, leading to poor performance. What works for one setup may not suit another. Continuous adjustments can yield different results. Data shows that 18% of systems run inefficiently due to lack of regular performance assessments. Monitoring tools are available, yet underused. Investing in training for staff can bridge this gap. Simple changes can yield significant improvements.

Digital Control Valve Performance Analysis

Impact of Digital Control Valves on Energy Efficiency and Operational Costs

Digital control valves play a crucial role in enhancing energy efficiency in industrial settings. They provide precise control over fluid flow, reducing waste and minimizing downtime. By optimizing flow rates, these valves can significantly lower energy consumption. For instance, a slight adjustment in valve position can impact the overall system performance positively.

However, not all installations achieve their intended efficiency. Many factors can affect performance, including incorrect calibration, valve sizing, and installation errors. A poorly configured digital control valve might lead to excessive energy use and increased operational costs. Regular maintenance and proper tuning can mitigate these issues, but they require time and resources.

Monitoring flow data in real-time can reveal hidden inefficiencies. Operators should keep an eye on unusual patterns or fluctuations in energy usage. If discrepancies are detected, revisiting the valve settings can lead to better efficiency. The goal is to ensure that each component effectively contributes to performance improvements. Balancing efficiency against operational costs remains a challenge, yet it is essential for sustainable operations.

Emerging Technologies and Trends in Digital Control Valve Systems

Digital control valve systems are evolving rapidly.

New technologies are enhancing their

performance and efficiency. Advanced sensors play a crucial role.

They provide real-time data. This data helps in making accurate adjustments.

Better feedback loops lead to smoother operation.

Emerging trends include the use of artificial intelligence.

AI can predict maintenance needs, reducing downtime. Predictive analysis based on historical data is becoming

standard. However, these systems require significant upfront investment. Many users hesitate to adopt

these technologies due to costs.

Integration with IoT continues to grow. Connected

devices allow for remote monitoring. This flexibility can improve

operational efficiency. But data security remains a concern. Cyber

threats can compromise these systems. Users must address these vulnerabilities effectively.

The journey towards optimal efficiency is ongoing, with much to learn.

Related Posts

-

Top 10 Benefits of Using Automatic Valves in Modern Plumbing Systems

-

2026 How to Choose the Right Safety Relief Valve for Your System?

-

How to Choose the Right Safety Valve for Your Application?

-

Top 10 Benefits of Using Automatic Valves in Industrial Applications

-

Exploring ASCO Solenoids: The Backbone of Modern Automation in Industries

-

How to Locate and Use a Natural Gas Shut Off Valve Safely