How to Choose the Right Safety Valve for Your Application?

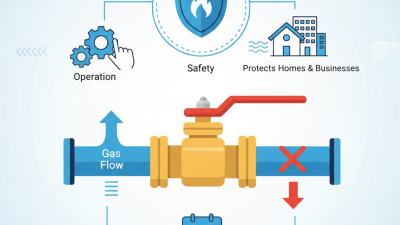

Choosing the right safety valve is crucial for your system's performance and reliability. Safety valves are essential in preventing overpressure situations in various applications. They serve as a safeguard, ensuring that pressure levels remain within safe limits.

When selecting a safety valve, consider factors like pressure range, connection size, and the type of media. Each application has unique needs. It's not as simple as picking any valve. An inappropriate choice can lead to system failures.

There are many factors to weigh. Think about the environment where the valve will be used. Certain materials might be more effective in specific conditions. The implications of a poor decision can be costly. Inadequate research can lead to safety hazards and equipment damage. Understanding your application's requirements is essential for making an informed choice.

Understanding the Role of Safety Valves in Industrial Applications

Safety valves play a crucial role in industrial applications. They are essential for protecting equipment and workers. In many industries, safety valves prevent overpressure conditions. This can prevent catastrophic failures and ensure operational safety.

According to a recent industry report, improper valve selection can lead to significant risks. It states that 70% of equipment failures result from inappropriate safety measures. This highlights the importance of choosing the right safety valve. In chemical plants, for instance, the correct valve can mitigate risks associated with hazardous materials. Not every situation fits a standard valve. Unique application conditions require careful consideration.

While many companies prioritize safety, some still overlook valve selection. A survey found that 30% of plants do not conduct regular safety audits. This negligence can lead to serious accidents. The right safety valve enhances system integrity. However, it is a complex decision. Factors such as pressure ranges and temperature variations complicate the choice. Continual learning and assessment are vital in this field. Each application has distinct requirements. Hence, selecting a valve requires both expertise and careful evaluation.

Key Factors to Consider When Selecting a Safety Valve

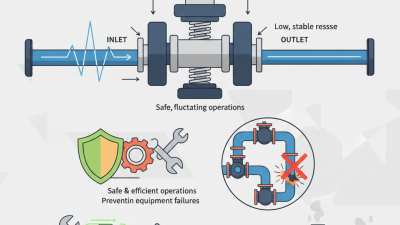

Choosing the right safety valve is crucial for ensuring the safety and efficiency of your system. Key factors to consider include pressure ratings, size, and materials. The pressure rating must match your system's operational conditions. If you underestimate this, you risk valve failure. Similarly, the size of the valve affects its performance. An oversized valve can lead to unnecessary costs. An undersized valve may not protect your system effectively.

Material selection is also essential. It should withstand the media it will encounter. For example, corrosive substances require specific materials. Do not overlook environmental conditions, such as temperature and humidity. Improper material choices can lead to degradation or failure. Consider installation requirements as well. Some valves may need more space or specific orientations.

Regular maintenance and operator training are often neglected. These factors can greatly impact valve performance. A lack of training can lead to incorrect adjustments, increasing risk. Ensure you review these aspects regularly. Reflecting on them can help identify potential issues before they arise.

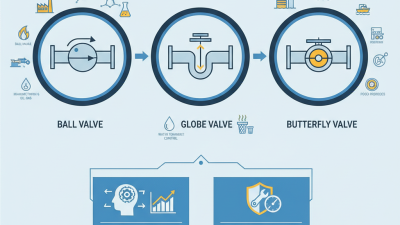

Types of Safety Valves and Their Suitable Applications

When selecting a safety valve, understanding the types available is crucial. There are generally three main types: spring-loaded, pilot-operated, and atmospheric. Each type has its unique mechanisms and is suited for different applications.

Spring-loaded valves are common in many industries. They work effectively for vapor and gas applications. Pilot-operated valves, on the other hand, are ideal for high-pressure and large flow capacities. They tend to be more efficient in managing pressure surges. Atmospheric valves are typically used in low-pressure situations and are mostly seen in systems where back pressure is minimal.

Tips: Consider the medium involved. Liquids and gases behave differently under pressure. Always check if the valve material is compatible with the fluid. This helps prevent failures.

You might find that some applications are not straightforward. A valve that works well in one scenario may not be suitable for another. Always reflect on the pressure level and the potential for fluctuations. Understanding this can save time and resources in the long run.

Material Compatibility and Design Standards for Safety Valves

When selecting a safety valve, material compatibility is crucial. Different environments demand different materials to handle specific pressures and temperatures. For example, valves made from stainless steel are suitable for high-temperature applications. However, they may not be compatible with certain corrosive substances. Reports indicate that 30% of valve failure incidents are due to material incompatibility. This highlights the need for careful selection based on the application's unique conditions.

Design standards also play a significant role. The American Society of Mechanical Engineers (ASME) sets rigorous standards for safety valves. These standards ensure that valves can operate safely under various conditions. Over 40% of industries rely on ASME codes for compliance. Choosing a valve that meets these standards can prevent accidents and ensure reliability. Yet, many companies overlook these regulations, resulting in costly failures. Regular training on standards could mitigate such issues.

While these aspects are fundamental, the industry must continue to adapt. New materials and technologies emerge, but proper education on their applications is often insufficient. Addressing this gap can enhance safety and performance in complex systems, leading to better overall outcomes.

Maintenance and Testing Requirements for Safety Valves

Maintenance and testing are crucial for safety valves. Regular checks can prevent failures. A poorly maintained valve may lead to leaks or, worse, catastrophic events. Visual inspections are the first step. Look for signs of wear, corrosion, or deformation. These signs can indicate that the valve is not operating at its best.

Testing the valve is equally important. Many facilities have protocols for routine testing. This includes verifying the lift pressure of the valve. If it doesn’t open at the specified pressure, something is wrong. Regular testing can uncover issues that are not immediately visible.

Documentation of all maintenance and testing is necessary. This helps in tracking performance trends over time. It’s common to find discrepancies in records. This can hinder effective maintenance strategies. Regular audits of these records can improve overall safety and reliability. Neglecting this aspect could potentially lead to regulatory issues and safety risks.

Related Posts

-

2026 How to Choose the Right Safety Relief Valve for Your System?

-

Top Electric Valves Types and Their Applications in Modern Industry?

-

Top 10 Valve and Automation Solutions to Boost Your Operations?

-

Understanding Pressure Relief Valves: Key Specifications and Their Crucial Role in Industrial Safety

-

What is a gas shut off valve and how does it work?

-

What is a Pressure Regulator and How Does it Work?