2026 How to Choose the Right Safety Relief Valve for Your System?

Choosing the right safety relief valve is crucial for system integrity and safety. In industrial operations, the right valve can prevent catastrophic failures. According to the American Society of Mechanical Engineers (ASME), over 60% of pressure-related incidents are due to improper valve selection. The safety relief valve is your last line of defense against excessive pressure build-up.

Selecting a safety relief valve involves understanding system requirements. These include the pressure rating, fluid type, and temperature conditions. Each valve type has specific applications, yet many do not account for changing conditions. Industry reports indicate that nearly 30% of safety relief valves are incorrectly sized, leading to inefficiencies and risks. This highlights the need for careful analysis and understanding.

The consequences of poor choices can be severe. Failure to choose the appropriate safety relief valve may result in equipment damage or, worse, endanger lives. It is vital to reflect on past incidents and learn from them. The goal should be to enhance safety and reliability by making informed, data-driven decisions. In this evolving industry, staying updated on best practices is essential for all operators.

How Safety Relief Valves Function in Pressure Management Systems

Safety relief valves play a critical role in pressure management systems. They protect equipment and personnel from overpressure situations. According to industry reports, approximately 60% of pressure-related incidents are due to faulty or inappropriate relief valves. Choosing the right valve is essential to maintain a safe and efficient system.

These valves operate by venting excess pressure. When the set pressure is reached, the valve opens to release fluid. This action lowers the pressure in the system. However, the wrong valve can lead to catastrophic failures. For instance, improperly sized valves can cause excessive wear and tear on machinery. Many operators fail to account for the specific requirements of their systems. They often choose standard options rather than bespoke solutions, leading to inefficiencies.

Regular maintenance of safety relief valves is crucial. Neglect can result in diminished performance. A study revealed that about 30% of valves are not tested regularly, increasing the risk of malfunction. The consequences of a failure can be severe. Investing in the right valve and routine checks can prevent costly accidents. Awareness and education in valve selection are key to enhancing system reliability.

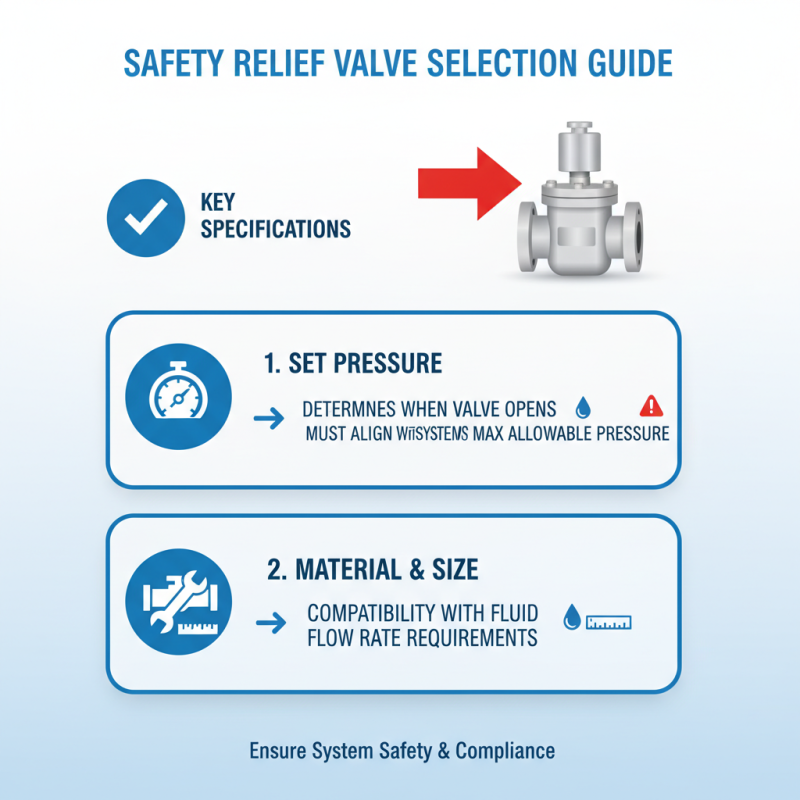

Key Specifications to Consider when Selecting a Safety Relief Valve

When selecting a safety relief valve for your system, consider several key specifications. The set pressure is crucial. It determines when the valve opens to relieve excess pressure. Make sure it aligns with your system's maximum allowable pressure.

The capacity of the valve is another important factor. It needs to handle potential overpressure situations effectively. A valve that is too small can lead to dangerous situations. On the other hand, an oversized valve may not function properly under low-pressure conditions.

**Tip:** Check the manufacturer’s specifications for flow rates. This will help you assess if a valve is suitable for your needs.

Materials of construction should match your system's medium. Corrosion resistance is vital, especially in harsh environments. Choosing the wrong materials could lead to frequent failures.

**Tip:** Look for valves with a track record of reliability. Sometimes, users overlook maintenance history.

Don't forget to look at the installation requirements. Space constraints can limit your options. A valve that fits well without excessive modifications is ideal.

**Tip:** Consult with engineers to ensure compatibility with your setup. This step can avoid costly mistakes.

Industry Standards and Regulations Impacting Safety Relief Valve Selection

When selecting a safety relief valve, industry standards play a vital role. Standards ensure that the valve meets required safety and performance metrics. Various organizations publish these guidelines. For example, the American Society of Mechanical Engineers (ASME) sets specific design and testing standards. These standards affect installation and maintenance as well.

Regulations can vary significantly. Local codes may impact your choices. Compliance isn't just a box to check; it's crucial for safety. Engineers must stay updated with changes in these regulations. A misunderstanding can lead to serious issues. Choosing a valve that doesn’t meet the standards can cause malfunctioning and safety hazards.

You should consider the application environment, too. Corrosive environments need special materials. Think about pressure and temperature ratings. Incorrect specifications can lead to premature failure. Not all valves are designed for every scenario. Evaluating your needs based on these guidelines may prevent costly mistakes in the long run.

Evaluating Material Compatibility for Safety Relief Valves in Different Environments

When choosing a safety relief valve, material compatibility plays a crucial role. Valves must withstand the operating environment. The wrong material can lead to failure. Consider factors like pressure, temperature, and fluid composition. Corrosion can significantly reduce valve lifespan. Choosing the right material can prevent costly leaks and failures.

Tips: Always consult material compatibility charts. Identify potential chemical interactions early. This proactive approach minimizes risks. A simple mistake might lead to major problems later.

Also, consider the surrounding environment. Humidity, temperature fluctuations, and contaminants can impact valve performance. Stainless steel is often a safe choice, but it’s not always the best. Sometimes, non-metal materials outperform metals. Don’t overlook the impact of these factors. Each choice you make deserves careful thought. Balancing cost and reliability is essential.

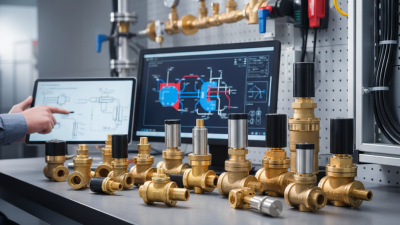

Material Compatibility Evaluation for Safety Relief Valves

Determining the Proper Sizing and Capacity for Your Relief Valve Needs

When selecting a safety relief valve, sizing and capacity are crucial. An appropriately sized valve prevents overpressure conditions. A valve too large may not close properly, while one too small could fail to vent adequately.

To determine the proper size, assess your system's operating pressure and flow rate. Calculate the required relieving capacity based on maximum possible discharge. This value is critical. Consider the nature of the fluid as well. Gas and liquid applications behave differently under pressure.

Keep in mind that improper sizing can lead to significant issues. A valve that doesn’t meet specifications might not function effectively, leading to safety risks. Regularly revisiting and reassessing your valve needs is essential. Adjustments based on system modifications are often overlooked. A thoughtful analysis can prevent costly mistakes and enhance safety.

Related Posts

-

Top 5 Relief Valve Options for Optimal Pressure Control in Industrial Applications

-

How to Choose the Right Asco Solenoid Valve for Your Application

-

2025 Guide: How to Choose the Perfect Dresser Utility for Your Space

-

2025 Top 10 Valve Actuators Revolutionizing Industrial Automation with 25 Percent Efficiency Increase

-

Top 10 Benefits of Using Automatic Valves in Industrial Applications

-

Exploring the Benefits of Installing a Water Pressure Relief Valve in Your Home Plumbing System