How to Choose the Right Pressure Control Valve for Your Needs?

Choosing the right pressure control valve is crucial for any system. A pressure control valve manages fluid pressure efficiently. The selection process may seem simple, but it requires careful thought.

Different applications demand different types of valves. Consider the specific requirements of your project. Factors include pressure range, flow rate, and fluid type. A valve that works well in one scenario may fail in another. It’s essential to ask the right questions.

Some users overlook details like the valve's response time. This can lead to issues down the line. Understanding your needs helps prevent costly mistakes. Ultimately, selecting the correct pressure control valve enhances performance and reliability. Investing time in this choice pays off in the long run.

Understanding Pressure Control Valves and Their Functions

Pressure control valves are essential components in many systems. They help maintain a specific pressure level, ensuring operational safety and efficiency. Understanding their functions is crucial before selecting the right valve. These valves automatically adjust flow and pressure, preventing overpressure scenarios that may lead to equipment damage.

Choosing the correct valve depends on various factors. The application type matters. Is it for hydraulic systems, pneumatic systems, or something else? Each has its unique requirements. The material of the valve can also affect performance and lifespan. Corrosion resistance might be necessary in some environments, while others require high-temperature handling.

Many users overlook sizing, which is critical. An undersized valve may lead to pressure drops. Oversized valves can waste energy and create stability issues. Testing and feedback loops are often necessary to identify the best fit. This process is not always straightforward and may require some trial and error. Understanding the specific needs of your system will ultimately guide you in making an informed choice.

How to Choose the Right Pressure Control Valve for Your Needs?

| Type of Pressure Control Valve | Function | Applications | Key Features | Choosing Criteria |

|---|---|---|---|---|

| Pressure Relief Valve | Protects systems from excess pressure | Hydraulic systems, steam boilers | Automatic operation, durable construction | System pressure limits, flow capacity |

| Pressure Reducing Valve | Maintains downstream pressure | Water distribution systems | Adjustable pressure settings, compact design | Desired outlet pressure, flow requirements |

| Back Pressure Valve | Maintains pressure in upstream systems | Chemical processing, oil and gas | Non-clogging design, high corrosion resistance | Upstream pressure needs, liquid properties |

| Signal Pressure Control Valve | Controls pressure based on external signal | Automated systems, industrial processes | Precision control, quick response times | Signal compatibility, required sensitivity |

Identifying Your Specific System Requirements for Pressure Control

When selecting a pressure control valve, identifying your system's specific requirements is crucial. Each system has its own pressure range, fluid type, and temperature conditions. Understanding these parameters helps narrow down your options. For example, if you're working with a high-temperature fluid, you'll need a valve that can withstand those conditions. This ensures durability and reliability in your system.

Consider the installation environment as well. Is the valve going indoors or outdoors? Exposure to elements can affect the type of materials you should choose. Moreover, different applications may require certain features such as manual overrides or fail-safe options. Assessing these needs can make a significant difference in performance.

It's easy to overlook details in the selection process. You might assume all valves behave similarly, but that's often not the case. Even slight variations in design can lead to inefficiencies. Therefore, take your time to evaluate your specific needs. Engage with professionals or conduct thorough research. Mistakes in this stage can be costly, both in repairs and system downtime.

Evaluating Different Types of Pressure Control Valves Available

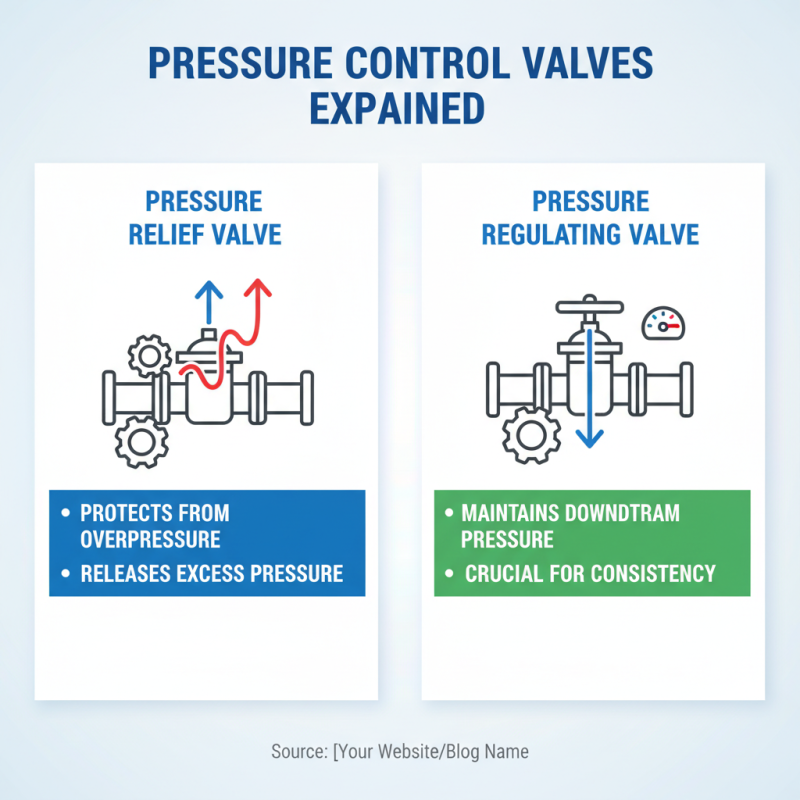

When evaluating different types of pressure control valves, it’s essential to understand their functions and applications. Pressure relief valves are designed to protect systems from overpressure. They release excess pressure by opening at a set point. Another type is the pressure regulating valve, which maintains a specified downstream pressure. These valves can be crucial for systems that require consistency.

Beyond the basic types, there are variations to consider. For instance, pilot-operated valves use a small pressure signal to control flow and can handle larger volumes. On the other hand, direct-acting valves are simpler. They function with less complexity but can struggle with larger fluctuations. Choosing between them can be challenging.

It’s also important to think about the installation environment. Factors like temperature, media type, and system pressure can influence valve performance. Not every valve suits every situation. Testing and evaluating different models can highlight what works best for specific applications. It’s a process that requires patience and reflection on previous choices. The right valve can lead to efficient system performance.

Determining Sizing and Specifications for Optimal Performance

When selecting a pressure control valve, understanding sizing and specifications is crucial. The valve size must align with the system's flow rate requirements. According to industry reports, nearly 40% of performance issues stem from improper sizing. An oversized valve may lead to instability, while an undersized valve causes insufficient pressure control. Balancing these factors is essential for system reliability.

Specifications like operating pressure and temperature also play a vital role. Reports suggest that 35% of failures occur due to inadequate temperature ratings. It's important to analyze the environment where the valve will be installed. For instance, a valve operating in high-temperature conditions needs materials that resist deformation. Proper materials impact longevity and efficiency.

Moreover, careful selection can significantly enhance system performance. Engineers must analyze not only the specifications but also potential wear over time. Regular assessments can uncover issues like erosion or material fatigue. Failing to consider these factors may result in costly downtime or even catastrophic failures. Ultimately, investing time in the right specifications leads to better performance and a safer operation.

Pressure Control Valve Selection: Key Parameters

Assessing Quality and Reliability in Pressure Control Valve Selection

When selecting a pressure control valve, quality and reliability are crucial. According to recent industry reports, over 30% of valve failures are due to poor quality. This highlights the importance of choosing valves that meet stringent quality standards. Look for certifications like ISO 9001 to ensure reliability.

Tips: Always check the material of the valve. It should withstand the operating conditions in your system. Ensure compatibility with fluids. Don’t rely solely on price. A cheaper option may lead to higher long-term costs due to failures.

Another consideration is the testing process. Many valves go through extensive testing before being approved. A report from the Valve Manufacturers Association states that rigorous testing can reduce failures by 40%. This data shows that investing in high-quality valves pays off.

Tips: Inquire about the testing protocols used. Reliable manufacturers share this information. Be cautious about shortcuts in production. They can compromise valve integrity. Carefully assess each option based on your specific needs. Remember, the right valve serves not just as a component, but as a cornerstone of your system’s reliability.

Related Posts

-

The Best 10 Pressure Control Valve Models for Optimal Performance?

-

2025 Top 10 Valve Actuators Revolutionizing Industrial Automation with 25 Percent Efficiency Increase

-

How to Optimize Valve and Automation Systems for Maximum Efficiency

-

2025 Guide: How to Choose the Perfect Dresser Utility for Your Space

-

2026 Top Valve Actuator Types You Should Know?

-

10 Essential Tips for Selecting the Right Control Valve for Your System?