Top 10 Benefits of Using Automatic Valves in Industrial Applications

In the ever-evolving landscape of industrial applications, the integration of advanced technologies is crucial for enhancing operational efficiency and ensuring safety. One such innovation that has gained prominence is the automatic valve, a crucial component that optimizes the control of fluid flow in various systems. With the increasing complexity of industrial processes, the demand for reliable and intelligent solutions is driving the adoption of automatic valves across diverse sectors.

Automatic valves offer a myriad of benefits that significantly improve both the performance and safety of industrial operations. From reducing manual intervention to enhancing process reliability, these valves streamline workflows while minimizing the risk of human error. Moreover, their ability to provide precise control and respond dynamically to changing conditions makes them an essential asset for modern industrial facilities. As we delve into the top 10 benefits of using automatic valves in industrial applications, it becomes evident how these innovative devices are transforming the way industries operate and manage their fluid systems.

Benefits of Automatic Valves in Enhancing Process Efficiency

Automatic valves play a critical role in enhancing process efficiency across various industrial applications. By enabling precise control of fluid flow, these valves significantly reduce the amount of manual intervention required, allowing for smoother operations. This automation leads to a more consistent process, minimizing the risk of human error and ensuring that systems run optimally under varying conditions. As a result, industries can maintain higher production rates while reducing downtime associated with manual adjustments or repairs.

Furthermore, the integration of automatic valves into industrial systems facilitates real-time monitoring and adjustments. This capability ensures that process parameters are kept within desired specifications, enhancing overall product quality. Automatic valves can be programmed to respond instantaneously to fluctuations in pressure or temperature, thereby preventing potential system failures or inefficiencies. The ability to achieve such precision not only bolsters safety but also leads to significant cost savings in both energy consumption and materials, demonstrating the transformative impact of automatic valves on process efficiency in industrial settings.

Top 10 Benefits of Using Automatic Valves in Industrial Applications

Reduction of Operational Costs Through Automated Valve Systems

The implementation of automatic valves in industrial applications can significantly reduce operational costs, a crucial aspect for companies striving for efficiency and profitability. According to a report by the International Society of Automation, organizations that adopt automated valve systems can achieve up to a 20% reduction in energy consumption. These systems operate at optimal levels without the constant need for manual intervention, which leads to less waste and improved resource management.

One of the most substantial cost-saving benefits arises from the increased reliability and maintenance reduction associated with automatic valves. A study by the Valve Manufacturers Association found that automatic valves can extend service intervals by up to 50%, minimizing downtime and maintenance expenditures. This longevity not only conserves labor resources but also enhances the overall productivity of industrial operations.

Tips: When considering the integration of automatic valves, it's crucial to conduct a thorough assessment of your current system's efficiency and identify areas where automation can add value. Additionally, training staff on the proper operation and maintenance of these systems can further enhance cost savings and operational reliability. Be sure to monitor the performance regularly to maximize benefits and identify any potential issues before they escalate into costly problems.

Improvement of Safety Standards in Industrial Operations with Automatic Valves

In industrial operations, safety is paramount, and the implementation of automatic valves plays a significant role in enhancing safety standards. Automatic valves are specifically designed to respond to changes in pressure, flow, or other parameters, ensuring that systems operate within safe limits. By automatically adjusting the flow of liquids or gases, these valves minimize the risks associated with human error, such as accidental overpressure or leaks, which can lead to hazardous situations.

Furthermore, automatic valves can enhance emergency response protocols by enabling rapid shutdowns in critical scenarios. When dangerous conditions are detected, these valves can close swiftly to prevent accidents, protecting both personnel and equipment. This proactive measure not only reduces the likelihood of incidents but also ensures compliance with strict safety regulations prevalent in heavy industries. By integrating automatic valves into their systems, organizations can foster a safer working environment, reinforcing their commitment to worker safety and environmental protection.

The Role of Automatic Valves in Energy Conservation in Manufacturing

Automatic valves play a critical role in enhancing energy conservation within manufacturing processes. By automatically regulating the flow of liquids and gases, these valves help maintain optimal operating conditions, reducing wastage and energy consumption. For instance, in systems where pressure and flow rates fluctuate, automatic valves can quickly adjust their positions to ensure consistent delivery of resources, preventing unnecessary energy losses associated with overpressurization or leaks.

In addition to maintaining efficiency, automatic valves contribute to energy conservation by enabling more precise control over manufacturing operations. By integrating advanced sensors and control systems, manufacturers can optimize their processes, aligning energy use with production demands. This level of control not only minimizes energy redundancy but also enhances overall system durability, as the equipment operates within designed parameters without the undue stress that can arise from manual interventions. As industries increasingly prioritize sustainability, the adoption of automatic valves becomes an essential strategy for achieving energy conservation goals and promoting more environmentally-friendly manufacturing practices.

Top 10 Benefits of Using Automatic Valves in Industrial Applications - The Role of Automatic Valves in Energy Conservation in Manufacturing

| Benefit | Description | Energy Savings (%) | Application Area |

|---|---|---|---|

| Increased Efficiency | Automatic valves optimize flow rates and reduce energy consumption. | 15% | Manufacturing |

| Reduced Labor Costs | Automation minimizes the need for manual intervention. | 10% | Processing Plants |

| Enhanced Safety | Automatic valve systems reduce the risk of human error during operations. | N/A | Chemical Industry |

| Consistent Performance | Automatic valves provide reliable control over various media. | 5% | Water Treatment |

| Lower Maintenance Costs | Durable automatic valves require less frequent maintenance. | 8% | HVAC Systems |

| Better System Control | Precise regulation of flow rates leads to improved system reliability. | 12% | Oil & Gas |

| Improved Product Quality | Stable processes enhance the quality of final products. | 7% | Food & Beverage |

| Remote Operation | Allows control from a distance for increased flexibility. | 20% | Utility Management |

| Energy Conservation | Effective control of utilities leads to significant energy savings. | 25% | Various Industries |

| Flexibility in Operations | Adaptable setups can be reconfigured as needed for efficiency. | 6% | Pharmaceuticals |

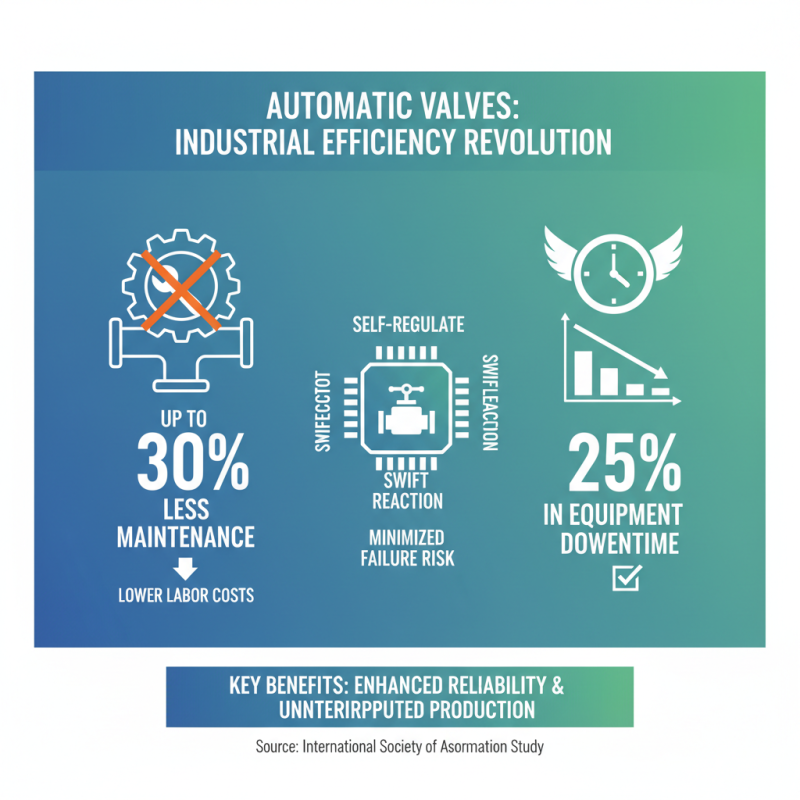

Maintenance and Downtime Reduction Achieved with Automatic Valve Technology

Automatic valves have become a staple in industrial applications due to their significant impact on maintenance and downtime reduction. Reports indicate that using automatic valves can decrease maintenance requirements by up to 30%, which translates to lower labor costs and a less interrupted workflow. For instance, a study by the International Society of Automation revealed that industries incorporating automatic valve technology experienced a 25% reduction in overall equipment downtime. This efficiency is largely attributed to the valves’ ability to self-regulate and react swiftly to changes in system conditions, minimizing the risk of failure.

Tips for optimizing your automatic valve system include regular system checks and updates to the automation software. Ensuring that your valves are compatible with the latest technologies can further enhance their operational lifecycle and improve reliability. Additionally, training staff on the nuances of automatic valve functions can help in identifying potential issues before they escalate, thereby effectively reducing unplanned maintenance events.

By integrating predictive maintenance strategies, companies can leverage data analytics to anticipate valve malfunctions and schedule upkeep accordingly, amplifying the benefits of automatic valves. Research indicates that predictive maintenance can lead to a 50% reduction in unscheduled downtime. By embracing automatic valves and predictive analytics, industries can safeguard against disruptions, ultimately leading to greater productivity and cost savings.

Related Posts

-

How to Choose the Right Automatic Valve for Your Industrial Needs

-

2025 Top Trends in Automatic Valves for Industry and Home Use

-

Understanding Pressure Relief Valves: Key Specifications and Their Crucial Role in Industrial Safety

-

Understanding Natural Gas Valves: Essential Guide to Safety and Efficiency in Your Home

-

Exploring the Benefits of Installing a Water Pressure Relief Valve in Your Home Plumbing System

-

2025 Guide: How to Choose the Perfect Dresser Utility for Your Space