2026 Best Electric Valves for Efficient Fluid Control?

Electric valves have become essential in many industries. They enable precise control of fluid flow, making processes more efficient. In 2026, several electric valves stand out for their performance and reliability.

These valves come in various designs, suitable for different applications. For example, some are great for high-pressure systems. Others excel in low-flow situations. The choice of electric valve can significantly impact overall efficiency. Users often overlook important features when selecting a valve, leading to suboptimal performance.

It's crucial to consider factors like durability and compatibility. Not all electric valves deliver the same results. Understanding specifications can be challenging, and mistakes can be costly. As we explore the best electric valves for 2026, we will highlight key aspects to consider and offer guidance for making informed choices.

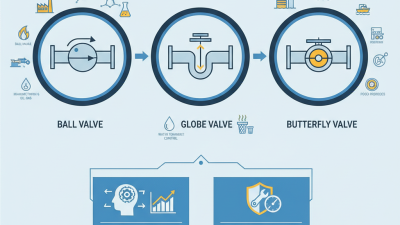

Overview of Electric Valves and Their Functionality

Electric valves play a crucial role in fluid control systems. They are electrically actuated devices that manage the flow of liquids or gases. Their functionality encompasses a wide range of applications across various industries. According to a recent industry report, the global electric valve market is projected to grow by 6.5% annually, reaching $8 billion by 2026. This growth is driven by increasing automation and a demand for efficiency.

One significant advantage of electric valves is their precision. They can be programmed for specific flow rates. Data shows that using electric valves can improve energy efficiency by up to 30%. However, there are challenges as well. Installation can be complicated, requiring skilled technicians. Maintenance is another concern. Reports indicate that up to 20% of electric valve failures are due to improper handling or installation.

As technology advances, the integration of smart sensors into electric valves is becoming commonplace. These sensors provide real-time data and feedback on valve performance. Nonetheless, reliability is not guaranteed. Some systems still struggle with issues like signal loss or sensor failures. The industry must address these issues to fully utilize electric valves’ potential in fluid management.

Key Features to Consider When Selecting Electric Valves

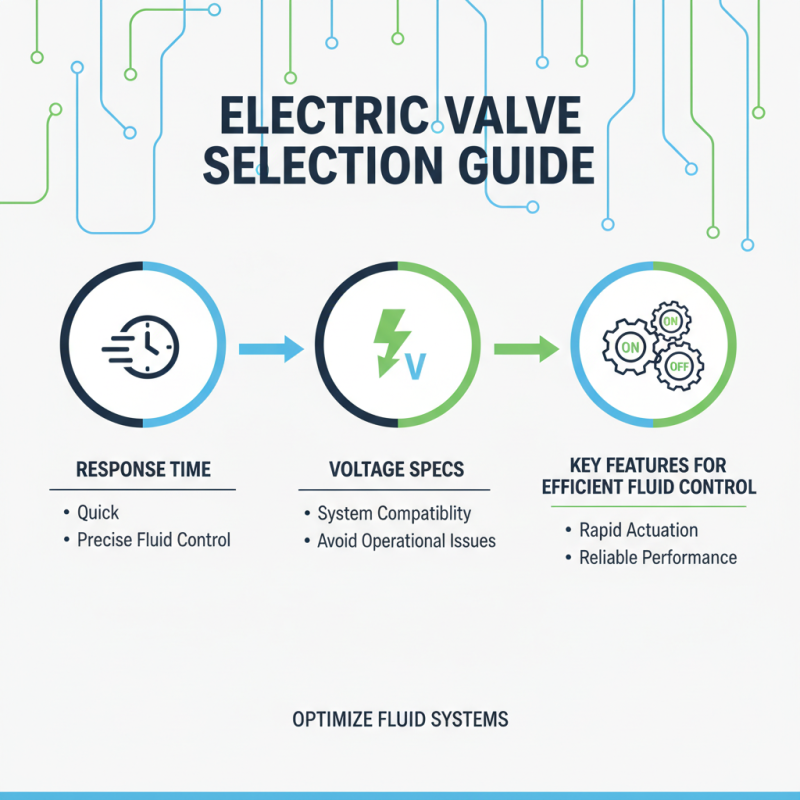

When choosing electric valves, specific features are crucial for efficient fluid control. One important aspect is the valve's response time. A quick response ensures precise fluid management, which is essential in many applications. Additionally, consider the voltage specifications. Different systems may require varying voltage levels for optimal performance. Misalignment with these requirements can lead to operational issues.

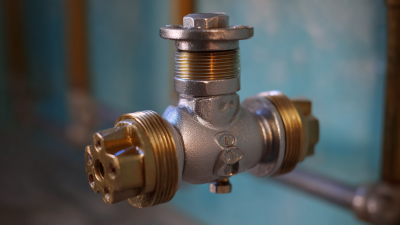

Another critical factor is the material of the valve. It must be compatible with the fluids being handled. For instance, corrosive fluids need valves made from resistant materials to prevent failure. Interestingly, many users often overlook maintenance needs. Regular maintenance can prevent unexpected breakdowns. Users should reflect on their specific environment and conditions.

Automation capabilities are also vital. Smart features can enhance control and monitoring. However, integrating complex systems may introduce challenges. Users must weigh these risks against potential efficiency gains. Electric valves should ultimately fit seamlessly into the existing system while providing reliable performance.

Top Brands and Models of Electric Valves for 2026

As the demand for fluid control systems advances, electric valves become essential. The market is projected to grow significantly, with a report estimating a CAGR of 7% from 2023 to 2028. Various models are emerging, each offering unique features designed for efficiency and reliability.

Top contenders in the electric valve market showcase varying degrees of performance. Some focus on precise control, while others prioritize durability in harsh environments. Many models now include smart technology for remote operation. However, the challenge remains: determining which model best suits specific applications.

Data shows a frequent gap in user experience reports. Many users face difficulties in integration with existing systems. This highlights the need for improved compatibility features in future designs. Investment in research and development can bridge this gap, leading to better, more responsive products. As the landscape evolves, it’s crucial for users to remain informed and adaptable.

Applications of Electric Valves in Various Industries

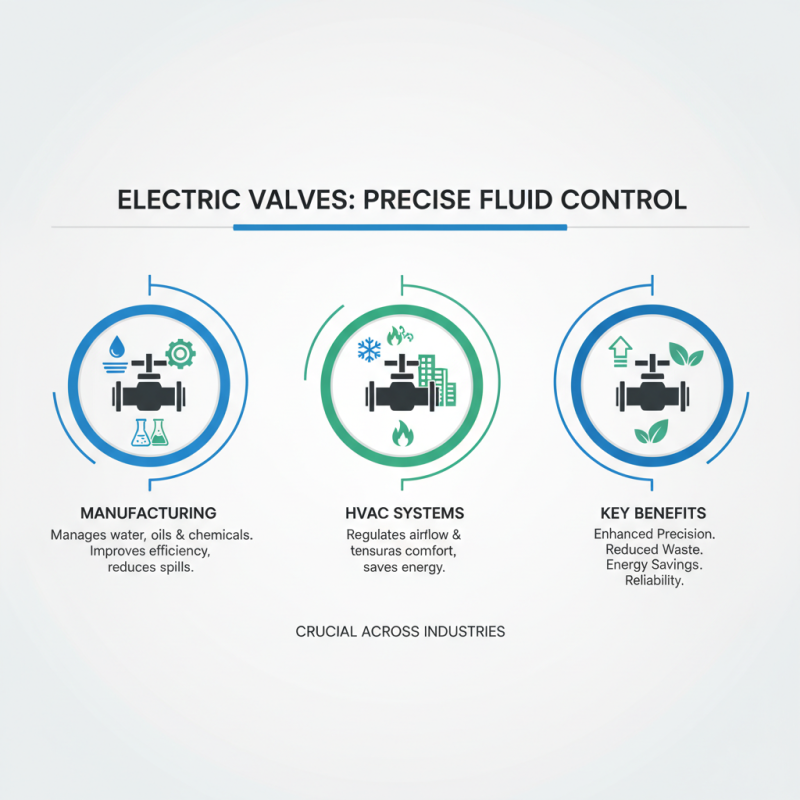

Electric valves are crucial in various industries, offering precise fluid control. In manufacturing, they manage water, oils, and chemicals. They improve efficiency and reduce spills. In HVAC systems, electric valves regulate airflow and temperature. This ensures comfort and energy efficiency in buildings.

In the food and beverage industry, electric valves control liquid flow accurately. Consistency is key for safety and quality. However, valve maintenance is often overlooked. Regular checks can prevent failures. It’s essential to train staff on proper handling to avoid mishaps.

When choosing electric valves, consider application specifics. Ensure compatibility with your system's requirements. Not all valves suit every operation. Evaluate their material and design carefully. Test before full-scale implementation to spot potential issues early.

Maintenance and Best Practices for Electric Valve Efficiency

Electric valves are essential for efficient fluid control in many industries. Proper maintenance practices can significantly enhance their performance. Regular inspection and servicing help identify potential issues early. According to industry reports, well-maintained electric valves can outperform unmaintained units by up to 30% in operational efficiency.

One crucial aspect of maintenance is lubrication. Many users overlook this step. A lack of proper lubrication can lead to wear and tear, affecting the valve's responsiveness. Another issue is the environment. Electric valves in harsh conditions may require more frequent checks. Dust and moisture can compromise functionality. A study indicated that 40% of electric valve failures are due to environmental factors.

Operators should also consider calibration as part of their routine. Incorrect settings may lead to inefficient fluid flow. In fact, a survey found that about 25% of operational issues stem from miscalibrated equipment. Training staff on best practices is vital. Regular skills updates can help prevent mistakes. Continuous improvement in maintenance strategies and practices is essential for long-term efficiency.

Related Posts

-

How to Choose the Right Automatic Valve for Your Industrial Needs

-

How to Choose the Right Valve and Automation Solutions for Your Industry Needs

-

How to Optimize Valve and Automation Systems for Maximum Efficiency

-

Top Electric Valves Types and Their Applications in Modern Industry?

-

Why You Need a Natural Gas Shut Off Valve for Home Safety and Maintenance

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency