2025 Top 5 Control Valve Trends Driving Efficiency in Industrial Applications

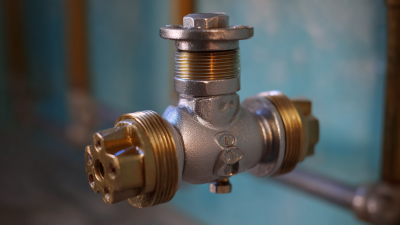

As industries continue to evolve, the importance of control valves in optimizing processes and enhancing operational efficiency cannot be overstated. In 2025, five key trends are expected to shape the control valve landscape, bringing innovative solutions that address the challenges faced by modern industrial applications. According to Dr. Emily Harrison, a renowned expert in flow control technologies, “The future of control valves will hinge on smart technology integration, enabling real-time monitoring and data-driven decision-making.” This insight highlights the growing role of advanced analytics and automation in the control valve sector.

Moreover, as industries strive for sustainability and cost-effectiveness, control valves are increasingly being designed with energy efficiency in mind. The transition towards eco-friendly practices demands that control valves not only regulate flow but also minimize energy consumption. As highlighting trends such as predictive maintenance and digital twins become more prevalent, the control valve industry stands ready to embrace these changes, improving not only performance but also safety and reliability in industrial operations.

In conclusion, the control valve sector is set to experience transformative advancements by 2025. With the guidance of industry visionaries like Dr. Harrison, companies are poised to adopt these trends, driving efficiency and sustainability across various applications. The evolution of control valves will undoubtedly play a pivotal role in shaping the future of industrial automation.

Innovative Technologies Redefining Control Valve Performance in 2025

As we progress towards 2025, innovative technologies are set to redefine control valve performance, significantly enhancing efficiency in industrial applications. Advanced materials and adaptive manufacturing techniques enable the production of valves that are not only more durable but also capable of withstanding extreme conditions. These innovations allow for better flow control and reduced losses, leading to increased overall operational efficiency.

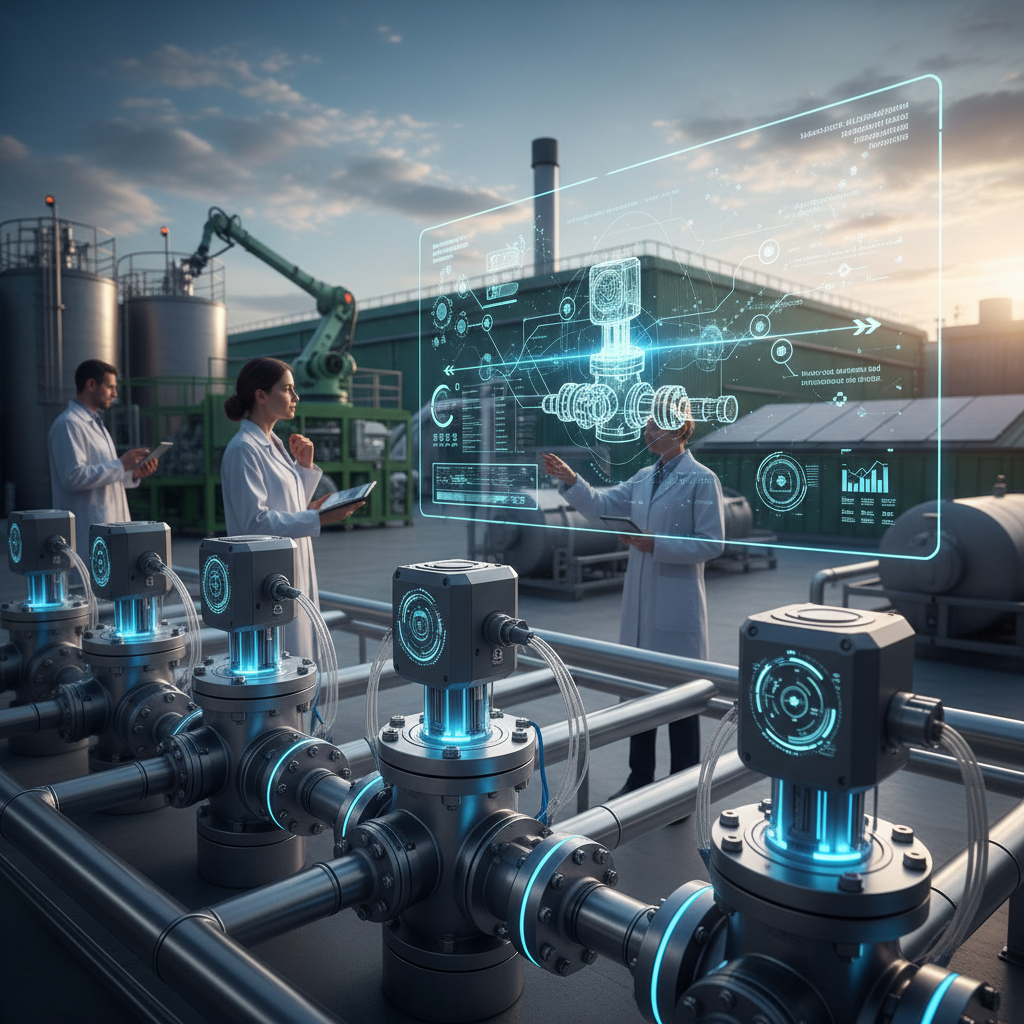

Furthermore, the integration of smart technology into control valves is transforming their functionality. IoT-enabled sensors and predictive maintenance algorithms improve monitoring and management, allowing for real-time data analysis and faster response to system changes. By leveraging artificial intelligence, these smart valves can learn from operating conditions, optimizing their performance to decrease energy consumption and emissions while maintaining precision in fluid control.

The convergence of these technologies heralds a new era for control valves in industrial settings. As industries seek to enhance their operational efficiency and sustainability, embracing these advancements will be crucial for achieving competitive advantage and meeting regulatory standards. With a focus on innovation, the future of control valves looks promising, paving the way for smarter and more efficient industrial processes.

Integration of Smart Automation in Control Valve Systems for Enhanced Efficiency

The integration of smart automation in control valve systems is significantly enhancing efficiency in industrial applications. According to a report by MarketsandMarkets, the global smart valves market is projected to reach $7.3 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.5% during the forecast period. This surge underscores the growing recognition of automation technologies as essential tools for improving process control and operational efficiency. By leveraging smart technologies, industrial facilities can reduce operational costs, optimize performance, and achieve better resource management.

Smart automation empowers control valve systems through advanced data analytics and real-time monitoring, enabling proactive decision-making and rapid responses to changing conditions. A study published by the International Society of Automation highlights that integrating artificial intelligence (AI) with control valves can reduce energy consumption by up to 30%. The adoption of IoT-enabled devices allows for better interconnectivity, facilitating seamless communication among control systems. As industries strive to enhance their operational efficiency, the implementation of smart automation in control valve systems will remain a key trend, ultimately leading to higher productivity and reduced downtime across various sectors.

Sustainability Initiatives Impacting Control Valve Design and Functionality

Sustainability has emerged as a driving force behind the evolution of control valve design and functionality in industrial applications. As companies strive to meet environmental regulations and adopt greener practices, control valves are being redesigned to improve efficiency and reduce waste. This shift is not only about complying with regulations but also about enhancing the overall performance of industrial processes. Innovations like smart control valve technology, which incorporates IoT capabilities, allow for better monitoring and optimization of fluid dynamics, ultimately leading to lower energy consumption.

**Tip: Consider integrating renewable energy sources into your valve control systems. This can significantly decrease operational costs and minimize your environmental footprint.**

Moreover, the focus on sustainability is pushing manufacturers to utilize eco-friendly materials and production processes. For instance, valves made from recycled materials or designed for easier disassembly contribute to a circular economy, reducing resource depletion. Companies adopting these practices not only enhance their operational efficiency but also improve their market position by appealing to environmentally conscious consumers.

**Tip: Regular maintenance of control valves can help maintain their efficiency and reduce energy losses, further supporting sustainability efforts in your operations.**

Data Analytics and Predictive Maintenance Trends in Control Valve Operations

In the realm of control valve operations, the implementation of data analytics and predictive maintenance is revolutionizing the industrial landscape. As industries strive for enhanced efficiency and reduced downtime, harnessing data analytics enables operators to monitor equipment in real-time, thus identifying potential issues before they escalate into costly failures. This proactive approach not only enhances the lifespan of control valves but also optimizes overall system performance.

Moreover, predictive maintenance driven by advanced analytics tools is becoming a standard practice in modern process automation. By analyzing historical data and operating conditions, companies can schedule maintenance activities more effectively, minimizing interruptions to production processes. As the demand for more sophisticated and reliable valve technologies continues to surge, industries are increasingly investing in innovations that leverage data-driven insights, underscoring the critical role of analytics in shaping the future of control valve operations.

2025 Top 5 Control Valve Trends Driving Efficiency in Industrial Applications

| Trend | Description | Impact on Efficiency (%) | Implementation Year |

|---|---|---|---|

| Data Analytics | Leveraging data for real-time decision making and monitoring. | 15 | 2023 |

| Predictive Maintenance | Preventative measures based on predictive analysis of equipment health. | 20 | 2024 |

| Smart Sensors | Integration of smart sensors for enhanced data collection. | 10 | 2025 |

| IoT Integration | Connecting devices for improved process control. | 18 | 2023 |

| Real-time Monitoring | Continuous assessment of valve performance optimizing operations. | 25 | 2025 |

Regulatory Changes Shaping the Future of Control Valve Selection and Usage

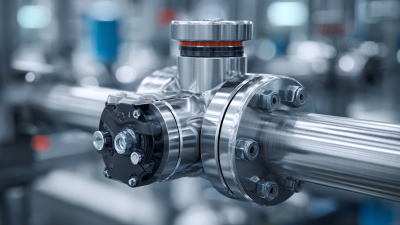

As regulatory frameworks evolve, the control valve industry must adapt to new standards that emphasize efficiency and environmental sustainability. Recent developments in greenhouse gas (GHG) emissions regulations drive industrial applications towards selecting advanced control valve solutions. Pressure-independent control valves (PICVs) are becoming increasingly prominent in the market, especially for hydronic applications, where they facilitate precise control of flow rates and reduce energy consumption. Reports indicate that implementing PICVs can lead to energy savings of up to 30%, significantly minimizing operational costs while also addressing regulatory compliance regarding emissions.

In addition to pressure-independent systems, the introduction of more stringent regulations by authorities, such as CARB, compels manufacturers to innovate while balancing engine efficiency and environmental impact. This push for cleaner technologies is evident in the latest diesel engines designed to minimize emissions without sacrificing performance. The adoption of such technologies in control valve applications is expected to grow, aligning with industry trends that seek to enhance operational efficiency while adhering to increasingly rigorous environmental standards. As these regulatory changes shape control valve selection and usage, the sector is poised for a transformation that prioritizes both performance and ecological responsibility.

Related Posts

-

Maximizing Efficiency with Asco Solenoids in Modern Automation Systems

-

Exploring ASCO Solenoids: The Backbone of Modern Automation in Industries

-

Top 10 Benefits of Using Automatic Valves in Modern Plumbing Systems

-

2025 Guide: How to Choose the Perfect Dresser Utility for Your Space

-

Understanding the Importance of Flow Control Valves in Modern Industrial Applications

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency