How to Choose the Right Valve and Automation Solutions for Your Industry Needs

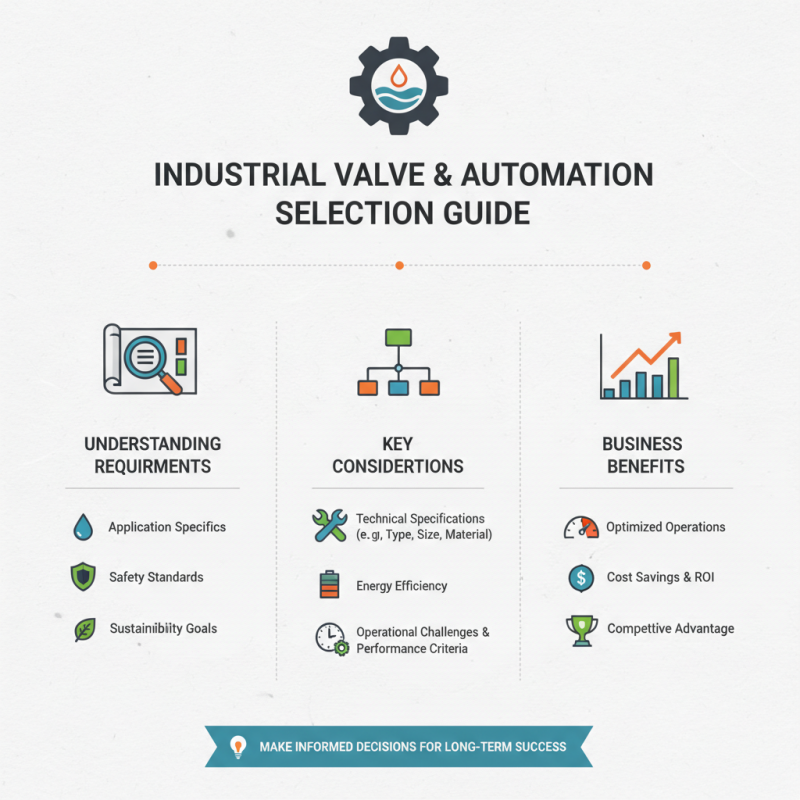

In today's fast-paced industrial landscape, choosing the right valve and automation solutions is crucial for optimizing operations and ensuring system efficiency. With a multitude of options available, industries must consider various factors that influence the selection process. Understanding specific requirements is key, as different applications demand distinct functionalities from valves and automation technologies.

The integration of superior valve and automation systems can lead to significant improvements in processes such as fluid control, safety, and energy efficiency. Furthermore, as industries grapple with increasing regulatory demands and the need for sustainability, selecting the appropriate solutions becomes even more critical. Companies must evaluate their unique operational challenges and performance criteria to make informed decisions that will ultimately enhance productivity and maintain competitiveness.

This guide aims to provide insights into the essential considerations for selecting valve and automation solutions tailored to your industry needs. By analyzing the various aspects involved, from technical specifications to the alignment with operational goals, you will be equipped to make sound choices that benefit your business in the long run.

Understanding Industry-Specific Requirements for Valves and Automation

When selecting valves and automation solutions for a specific industry, it's crucial to grasp the unique requirements that vary across sectors. For instance, the oil and gas industry demands valves capable of withstanding extreme pressure and temperature conditions. According to a report by Grand View Research, the global oil and gas valves market is expected to reach USD 21.4 billion by 2025, highlighting the growing need for robust and efficient valve solutions in this sector. Companies must prioritize features such as corrosion resistance and material compatibility to ensure long-term reliability and efficiency.

In the chemical processing industry, valves must comply with stringent safety and environmental regulations. A study by the International Society of Automation suggests that more than 30% of chemical plant shutdowns are due to valve failures. Thus, selecting high-performance automation solutions that facilitate real-time monitoring and diagnostics can significantly mitigate risks. Moreover, integrating smart technology can optimize operational efficiency and reduce maintenance costs, making it imperative for decision-makers to evaluate the automation capabilities alongside conventional valve specifications tailored to their specific applications.

Valve and Automation Solutions Needs Across Industries

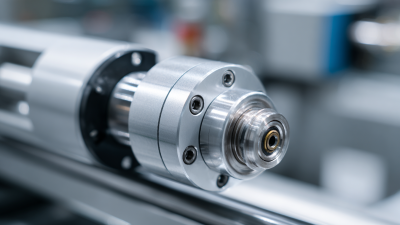

Types of Valves and Their Applications in Different Industries

Valves play a critical role in various industries, serving as essential components for controlling the flow of fluids and gases. Each type of valve has specific applications tailored to the unique requirements of different sectors. For instance, gate valves are commonly used in water treatment facilities due to their ability to provide a straight-line flow with minimal pressure loss. They are particularly effective in on/off applications where complete closure is necessary. Conversely, globe valves are favored in applications requiring precise flow regulation, such as in chemical processing plants where controlling the rate of flow is crucial for safety and efficiency.

In the oil and gas industry, ball valves are a popular choice due to their straightforward design and quick operation. Their ability to seal tightly makes them ideal for isolating sections of pipelines, minimizing leakage in high-pressure environments. Butterfly valves are also prevalent, particularly in large-diameter piping systems, owing to their lightweight and compact nature, allowing for easy operation and installation. With a wide range of valve types available, understanding their specific functions and applications ensures that industries can select the most efficient solutions to meet their operational needs.

How to Choose the Right Valve and Automation Solutions for Your Industry Needs

| Valve Type | Applications | Industry | Key Features |

|---|---|---|---|

| Gate Valve | On/Off Service | Oil and Gas | Low Pressure Drop |

| Ball Valve | Shut Off Applications | Chemical Processing | Quick Operation, Durable |

| Butterfly Valve | Flow Regulation | Water Treatment | Compact Design |

| Globe Valve | Throttling Control | Power Plants | Good Flow Control |

| Check Valve | Prevent Backflow | HVAC Systems | Automatic Operation |

| Pressure Relief Valve | Pressure Control | Refineries | Safety Device |

Key Factors to Consider When Selecting Valve Solutions

When selecting valve solutions for your industry needs, it is essential to consider several key factors that can significantly impact performance and efficiency. One of the foremost considerations is the operating environment. Valves must endure specific temperature, pressure, and chemical conditions, making it crucial to select materials that are compatible with the substances they will handle. Additionally, understanding the flow characteristics and whether your application requires throttling, on/off control, or pressure regulation can guide you in choosing the right type of valve.

Another important factor is the ease of maintenance and accessibility of the valve system. Valves that are complicated to access or maintain can lead to increased operational downtime and costs. Opting for designs that allow for simpler maintenance procedures and readily available parts can enhance long-term operational reliability. Finally, consider the automation needs of your application. Integrating advanced automation solutions can greatly improve efficiency, allowing for better control and monitoring of valve operations.

Ensuring compatibility with existing control systems and evaluating the potential for future scalability are crucial steps in selecting the right valve and automation solutions tailored to your requirements.

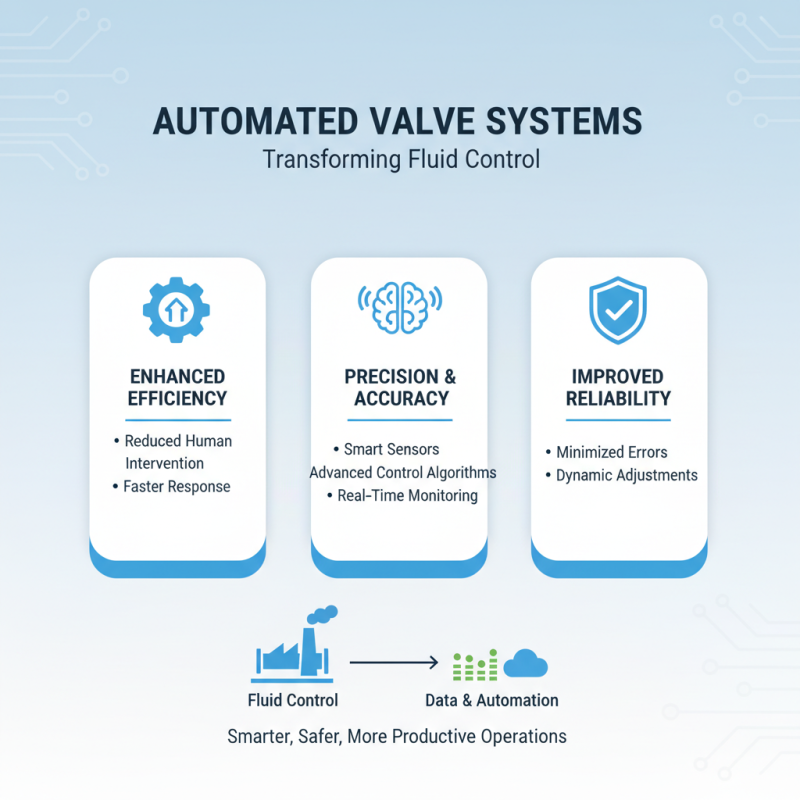

Integration of Automation Technologies in Valve Systems

The integration of automation technologies in valve systems has transformed how industries operate, enhancing efficiency and accuracy in fluid control processes. By incorporating smart sensors and advanced control algorithms, automated valves can provide real-time monitoring and precise adjustments, responding dynamically to varying operational conditions. This not only minimizes human intervention but also significantly reduces the risk of errors, improving overall system reliability.

Moreover, the incorporation of automation in valve systems facilitates better data collection and analysis. Real-time data from automated valves can be analyzed to optimize performance, predict maintenance needs, and track system health. This predictive maintenance approach allows industries to perform necessary interventions before failures occur, ultimately reducing downtime and associated costs. As industries seek to enhance productivity and sustainability, the integration of automation technologies into valve solutions is becoming increasingly essential, enabling them to meet the challenges of modern manufacturing and processing environments effectively.

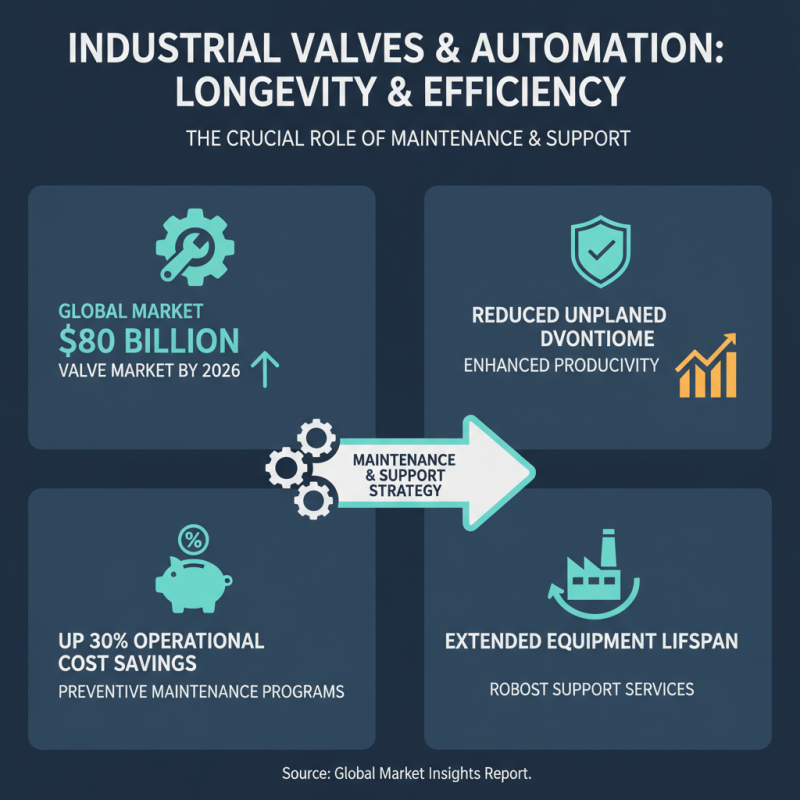

Maintenance and Support Options for Valves and Automation Solutions

When selecting valve and automation solutions for specific industry needs, maintenance and support options play a crucial role in the longevity and efficiency of the equipment. According to a report by Global Market Insights, the global valve market is projected to reach $80 billion by 2026, signaling a growing demand for robust support services. Regular maintenance can significantly reduce unexpected downtime, which in turn enhances productivity. Industrial facilities often underestimate the importance of a comprehensive maintenance strategy; studies indicate that preventive maintenance programs can lead to operational cost savings of up to 30%.

To ensure optimal performance, it is essential to consider the type of maintenance plans available. Options typically include preventive maintenance, which focuses on regular inspections and service to prevent failure, and predictive maintenance, which utilizes data analytics to anticipate equipment failures before they occur. A report from the International Society of Automation (ISA) highlights that predictive maintenance can increase operational uptime by up to 25% compared to reactive strategies. Choosing the right maintenance and support options tailored to valve and automation systems not only safeguards operational integrity but also yields significant financial benefits in the long run.

Related Posts

-

2025 Top 5 Control Valve Trends Driving Efficiency in Industrial Applications

-

How to Choose the Right Automatic Valve for Your Industrial Needs

-

Maximizing Efficiency with Asco Solenoids in Modern Automation Systems

-

Top 10 Benefits of Using Automatic Valves in Modern Plumbing Systems

-

Exploring the Future of Valve Automation and Control in Sustainable Energy Solutions

-

2025 Guide: How to Choose the Perfect Dresser Utility for Your Space