2025 Top Trends in Automatic Valves for Industry and Home Use

The evolution of automatic valves is a testament to the ongoing innovation within both industrial and residential applications. As technology advances, automatic valves are becoming increasingly sophisticated, addressing the demand for efficiency, safety, and automation in fluid control systems. In 2025, we can expect to see several key trends that will shape the landscape of automatic valve technology, significantly impacting various sectors by enhancing operational performance and sustainability.

One prominent trend is the integration of smart technology in automatic valves, allowing for real-time monitoring and remote operation. This capability not only improves system reliability but also fosters proactive maintenance, reducing downtime and operational costs. Additionally, the growing emphasis on energy efficiency and environmental responsibility is driving the development of automatic valves that minimize waste and optimize resource usage. As these trends unfold, both industries and homeowners will benefit from a new generation of automatic valves that are not only smart and efficient but also tailored to meet the unique demands of modern applications.

Emerging Technologies in Automatic Valve Design and Functionality

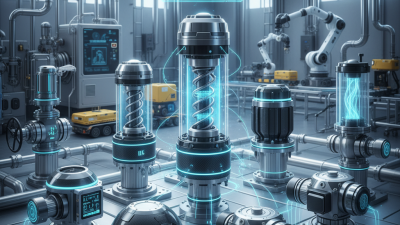

The landscape of automatic valves is evolving rapidly, with emerging technologies setting the stage for enhanced design and functionality. One of the most exciting advancements is the integration of smart sensors that allow for real-time monitoring and automated adjustments based on system conditions. These sensors enhance efficiency and reduce the likelihood of failure, making them invaluable for both industrial applications and residential use.

Tip: For those considering automatic valves for their home or industry, look for models equipped with IoT capabilities. These smart valves can provide remote control and diagnostics, ensuring optimal performance without the need for constant manual oversight.

Additionally, developments in materials science are paving the way for lighter, more durable valve designs. Innovations such as composite materials not only reduce wear and tear but also make installation simpler and adjustments easier. This is particularly beneficial in tight spaces where traditional valves may falter.

Tip: Before purchasing automatic valves, evaluate the material and weight specifications. Lighter valves can simplify installation, potentially leading to cost savings on labor without compromising on strength and reliability.

Key Innovations Shaping Automatic Valves for Industrial Applications

The automatic valves market is witnessing significant innovations that are set to reshape industrial applications. As industries strive for greater efficiency and safety, the demand for high-purity valves has surged. According to a recent market report, the global market for high-purity valves is projected to reach $2.26 billion by 2024, with expectations to grow to $3.45 billion by 2033, reflecting a compound annual growth rate (CAGR) of 4.81% during the forecast period. This growth is driven by the increasing need for precision and control in manufacturing processes across various sectors.

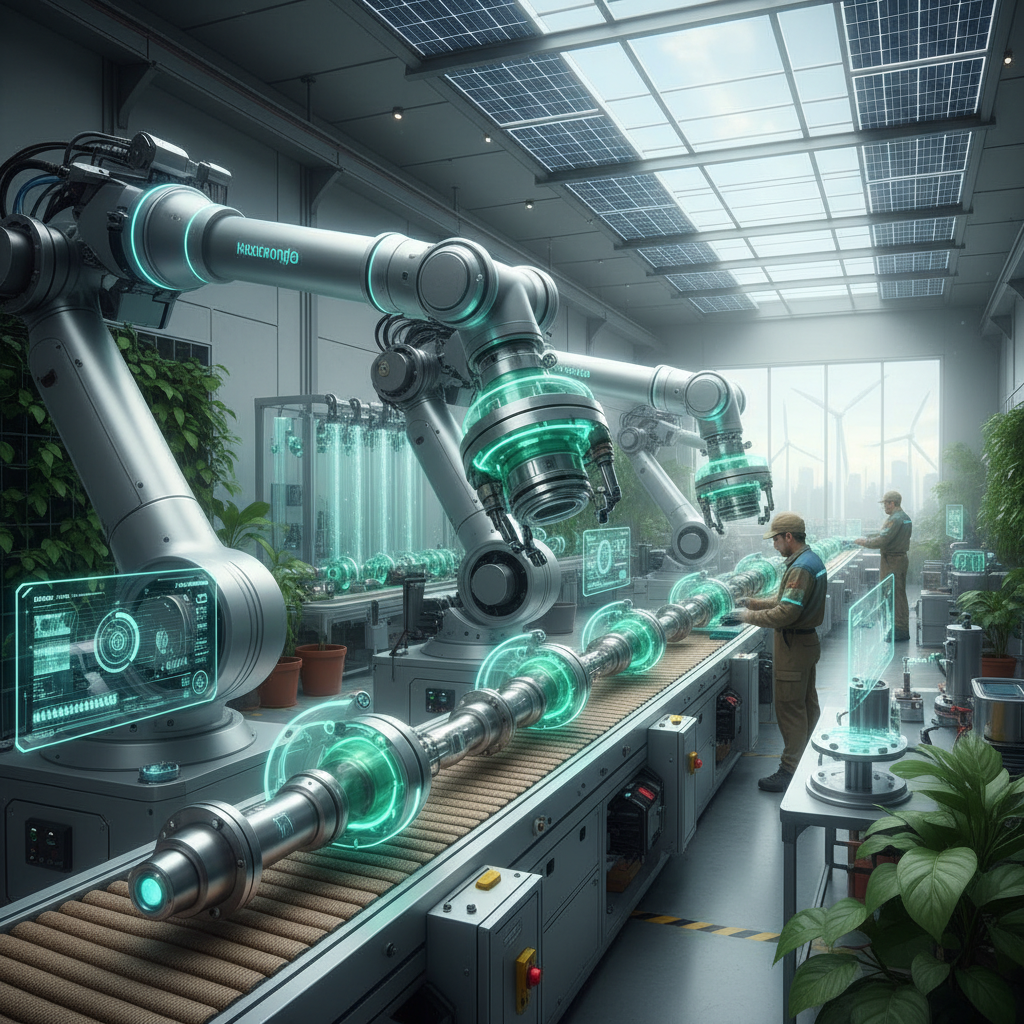

Key trends emerging in the automatic valves segment include advancements in smart technology integration and enhanced materials that resist corrosion and contamination. The implementation of IoT-enabled valve systems is helping industries achieve real-time monitoring and control, ultimately optimizing operations and reducing downtime. As the sector evolves, companies are also exploring innovative designs that cater to specific application needs, highlighting the importance of customization in meeting industry demands. These developments are not only enhancing operational efficiency but are also contributing to sustainable practices in production environments.

The Role of Smart Automation in Home Valve Systems

The evolution of home automation is significantly shaping the landscape of valve systems, revolutionizing how we control water, gas, and heating systems in our living spaces. Recent reports indicate that the remote control systems market for valves is projected to grow significantly, with a notable surge driven by the adoption of smart automation technologies. By 2034, this sector is expected to experience robust growth as consumers increasingly prioritize convenience and efficiency in their homes.

Government initiatives aimed at promoting smart factories reflect a broader trend that benefits domestic valve control systems. In March 2024, a landmark event highlighted this commitment, where the Ministry of SMEs and Startups in South Korea announced a substantial investment of $18.5 million to support intelligent factory projects. Such investments underpin the vital role of intelligent valve control systems in enhancing operational efficiency and reliability, creating a ripple effect that encourages home users to adopt similar technologies for their residential systems. With smart valves capable of being integrated into IoT frameworks, homeowners can expect unparalleled control and monitoring capabilities, representing a significant step towards fully automated living environments.

Sustainability Trends Impacting Valve Manufacturing and Usage

As the world increasingly prioritizes sustainability, the automatic valve industry is evolving to meet environmental demands. Valve manufacturing processes are now adopting greener technologies that minimize waste and energy consumption. Manufacturers are exploring innovative materials, such as biodegradable plastics and recycled metals, which reduce the ecological footprint of valve production. This shift not only enhances the sustainability of the final product but also aligns with global initiatives to decrease carbon emissions across various sectors.

In addition to greener manufacturing practices, users of automatic valves are becoming more conscious of their operational efficiency and longevity. Smart technologies are being integrated into valve systems, allowing for real-time monitoring and optimization of water or gas flow. These advancements lead to reductions in resource waste and improve overall energy efficiency in both industrial and home settings. Consumers are increasingly demanding these sustainable solutions, driving the market toward smart, eco-friendly valve options that contribute positively to the environment while still providing reliable performance.

Future Prospects and Challenges for Automatic Valves in Various Industries

The future of automatic valves in various industries is poised to tackle several challenges while embracing emerging trends. As industries continue to evolve, the need for enhanced automation and reliability in fluid control systems becomes increasingly evident. Automatic valves offer precision control, reducing human error and improving operational efficiency. However, ensuring compatibility with evolving technologies, such as IoT and AI, remains a critical challenge. Industries must adapt their automatic valve systems to integrate with smart technologies for predictive maintenance and real-time monitoring.

In addition to technological integration, automatic valves face sustainability challenges. The push for eco-friendly practices compels manufacturers to design valves that not only perform efficiently but also utilize materials that minimize environmental impact. The transition to renewable energy sources further necessitates the development of automatic valves that can handle diverse and sometimes volatile media. Adapting to these challenges will enable industries to leverage the benefits of automatic valve systems while contributing to broader environmental goals, ultimately driving innovation and securing competitive advantages in an increasingly automated future.

2025 Top Trends in Automatic Valves for Industry and Home Use

This chart illustrates the projected adoption rates of key trends in automatic valves for the year 2025. The trends include smart valves, eco-friendly materials, IoT integration, energy efficiency, and cost reduction, highlighting the future prospects and challenges in various industries.

Related Posts

-

How to Choose the Right Automatic Valve for Your Industrial Needs

-

2025 Top 5 Control Valve Trends Driving Efficiency in Industrial Applications

-

Top 10 Benefits of Using Automatic Valves in Modern Plumbing Systems

-

Exploring the Benefits of Installing a Water Pressure Relief Valve in Your Home Plumbing System

-

Top 5 Relief Valve Options for Optimal Pressure Control in Industrial Applications

-

2025 Top 10 Valve Actuators Revolutionizing Industrial Automation with 25 Percent Efficiency Increase